2025 Top 10 Robotic Welding Automation Trends You Need to Know

As we approach 2025, industries around the globe are gearing up to embrace transformative technologies that offer both efficiency and precision. Among these, robotic welding automation stands out as a critical trend set to redefine manufacturing processes. In recent years, the integration of robotics into welding operations has progressed at an unprecedented pace, reflecting advancements in AI, machine learning, and sensor technologies. Companies looking to maintain a competitive edge must stay informed about the latest innovations in this field.

In this article, we will explore the top 10 robotic welding automation trends that you need to know. From enhanced precision and quality control to reduced operational costs, these trends promise to revolutionize traditional welding practices. Additionally, we will examine how businesses can leverage these advancements to optimize their workflows and improve overall productivity. Understanding these emerging trends is essential for anyone involved in manufacturing, as the future of welding rests firmly on the shoulders of automation and robotics.

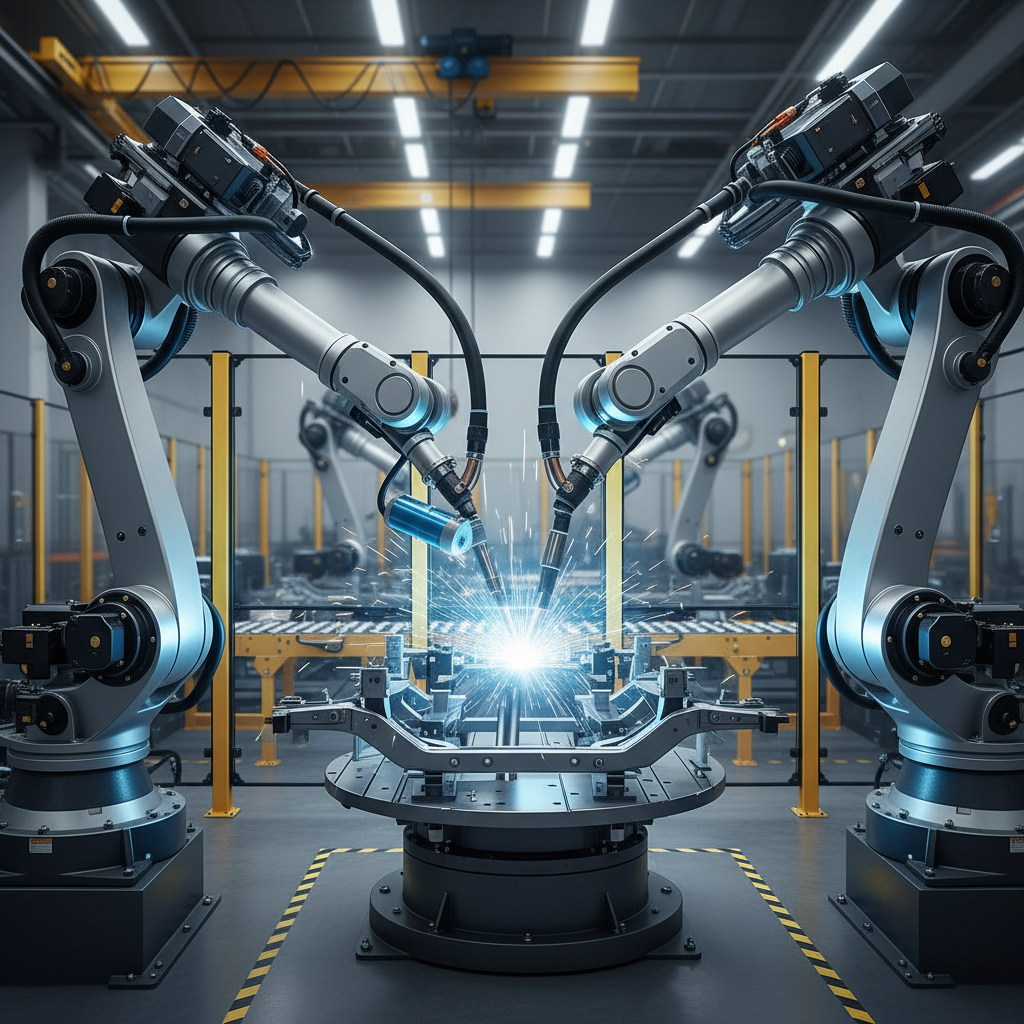

Emerging Technologies in Robotic Welding Automation for 2025

Emerging technologies in robotic welding automation are set to revolutionize the manufacturing landscape by 2025. With the integration of AI and Industry 4.0 principles, companies are witnessing unprecedented precision and efficiency in automotive production. The latest advancements include collaborative welding robots that enhance productivity while ensuring safety in the workspace. The trends indicate a shift towards more smart automation solutions, making it easier for manufacturers to respond to market demands swiftly.

Tips: To stay ahead in the evolving landscape, manufacturers should consider investing in modular automation solutions that allow for flexibility and scalability. Additionally, adopting AI-driven robotics can provide valuable insights through data analytics, enabling better decision-making and resource management.

As industries grapple with automation’s impact on labor markets, it’s crucial to retrain and upskill employees to adapt to new technological environments. Embracing robotics and AI not only transforms production processes but also creates opportunities for a more skilled workforce equipped to handle advanced manufacturing tasks. Investing in workforce development will ensure that companies can fully leverage the potential of new technologies while contributing to a more resilient economy.

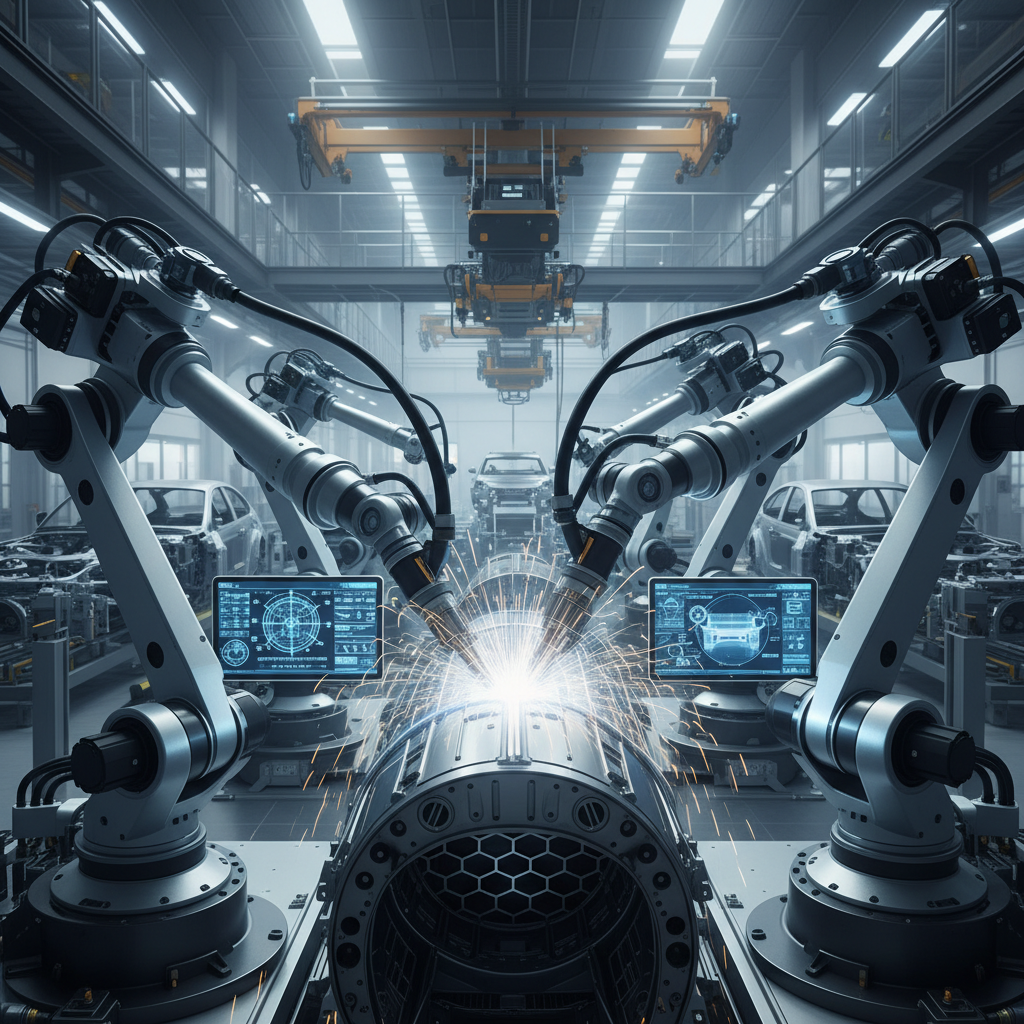

Integration of AI and Machine Learning in Welding Processes

The integration of AI and machine learning in welding processes is revolutionizing the industry, marking a significant shift towards more efficient and precise robotic welding automation. According to a recent report by MarketsandMarkets, the global robotics market in the welding industry is projected to reach $5.5 billion by 2025, driven largely by these advancements. AI-powered systems are now capable of analyzing real-time data from welding operations, allowing for adaptive learning and improved quality control. This minimizes defects and rework, which can cost manufacturers up to 20% of their total production costs.

Furthermore, the ability of machine learning algorithms to predict equipment failures and maintenance needs is enhancing the reliability of welding operations. A study by Frost & Sullivan indicates that integrating AI into manufacturing processes can yield productivity improvements of 30% to 50%. As organizations increasingly adopt these technologies, they can expect increased capacity utilization and higher throughput. The transition toward AI-driven welding not only enhances operational efficiency but also positions companies at the forefront of innovation in the manufacturing sector.

2025 Top 10 Robotic Welding Automation Trends You Need to Know

| Trend | Description | Impact |

|---|---|---|

| AI-Driven Quality Control | Utilizing AI algorithms to monitor weld quality in real-time. | Increased reliability and reduction in rework costs. |

| Predictive Maintenance | Using machine learning to predict equipment failures before they happen. | Reduced downtime and maintenance costs. |

| Adaptive Welding Technology | Systems that can adjust welding parameters on-the-fly. | Improved weld quality and adaptability to different materials. |

| Robotic Process Automation (RPA) | Integration of RPA to streamline welding workflows. | Enhanced efficiency and reduced operational costs. |

| Enhanced Simulation Software | Use of advanced simulation tools to optimize welding processes. | Higher accuracy and better planning of welding tasks. |

| Data Integration Platforms | Centralized data management for welding parameters and outcomes. | Improved decision-making and process optimization. |

| Cybersecurity in Automation | Implementing robust security measures in automated welding systems. | Protection against data breaches and operational disruptions. |

| Remote Monitoring and Control | Ability to monitor and control welding machines from remote locations. | Increased flexibility and faster response times. |

| Sustainability in Welding Processes | Focus on reducing waste and energy consumption in welding. | Lower environmental impact and compliance with regulations. |

Advancements in Robotic Welding for Complex Joint Configurations

The landscape of robotic welding is evolving rapidly, driven by advancements that address the challenges of complex joint configurations. As manufacturers strive for greater precision and efficiency, robots are becoming increasingly sophisticated in their capabilities. Recent innovations in artificial intelligence and machine learning allow robotic systems to analyze intricate joint designs and adjust parameters in real-time, ensuring optimal weld quality and consistency. These developments are especially crucial in industries such="aerospace" style="color: #FF5733; text-decoration: underline;"> aerospace and automotive, where the integrity of joints plays a vital role in overall safety and performance.

Moreover, the integration of advanced sensing technology is revolutionizing the way robotic welding systems operate. Equipped with sensors that provide feedback on temperature, position, and weld pool characteristics, these robots can now perform adaptive welding processes. This means that they can automatically modify their techniques based on the specific requirements of each joint, accommodating variations in material thickness and alloy composition. Consequently, manufacturers are seeing reduced scrap rates and improvements in production timelines, making robotic welding a more viable option for handling complex configurations in a cost-effective manner.

Enhanced Safety Protocols in Robotic Welding Applications

The rise of robotic welding automation is revolutionizing manufacturing, with enhanced safety protocols becoming a paramount focus. As industries integrate advanced robotic systems, the need for stringent safety measures has never been greater. These protocols not only protect workers but also ensure the integrity of the welding process. One key aspect of enhanced safety is the implementation of real-time monitoring systems that can detect anomalies in machine operation, alerting operators to potential risks before they escalate.

Additionally, new technologies such as collaborative robots (cobots) are designed with inherent safety features that allow them to work alongside human operators without the need for extensive safety barriers. These cobots utilize advanced sensors and machine learning algorithms to predict and react to human movement, significantly reducing the likelihood of accidents. As manufacturers adopt these innovations, training programs are also evolving, focusing on educating employees about these new safety technologies and protocols. This holistic approach not only enhances workplace safety but also fosters a culture of precaution within the industry.

Sustainable Practices and Energy Efficiency in Welding Automation

As we move towards 2025, the integration of sustainable practices and energy efficiency in robotic welding automation is becoming more prominent. Industries are increasingly recognizing the need to adopt eco-friendly technologies to minimize their carbon footprint. The global industrial automation market is projected to reach $209.9 billion by 2025, with a compound annual growth rate (CAGR) of 8.5% from 2025 to 2035. This highlights a significant transformation where energy efficiency is a key driver.

Tips: To ensure optimal energy consumption in welding automation, consider automating your processes with smart robots that can adjust power usage based on demand. Additionally, implementing laser cleaning technology can significantly enhance surface preparation in welding while reducing waste, as the market for laser cleaning is expected to grow steadily, reflecting the industry's shift towards sustainable practices.

By focusing on energy-efficient systems and cleaner technologies, manufacturers can not only comply with regulatory standards but also realize cost savings in the long run. The trend towards greener production methods is not just a compliance issue; it's a strategic business advantage in a competitive market.

2025 Top 10 Robotic Welding Automation Trends

The following bar chart illustrates the top trends in robotic welding automation expected for 2025, focusing on sustainable practices and energy efficiency. These trends reflect the industry's shift toward greater efficiency and lower environmental impact.

Related Posts

-

Revolutionizing Manufacturing: The Impact of Automated Welding Cells on Production Efficiency

-

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

-

The Future of Manufacturing How Robotic Welding Machines Are Revolutionizing the Industry

-

2025 Top 5 Robotic Welding Classes for Advanced Skills and Career Growth

-

Exploring the Future: Top Robotic Systems to Watch in 2025

-

What is Robot Parts? A Comprehensive Guide to Components and Their Uses in Robotics