Top 10 Benefits of Using Robotic Welding Machines in Modern Manufacturing

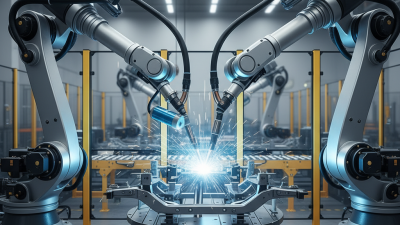

In the realm of modern manufacturing, the integration of technology has become a cornerstone of operational efficiency and productivity. Among the array of advanced manufacturing solutions, the robotic welding machine stands out as a transformative tool that revolutionizes traditional welding processes. According to a report by MarketsandMarkets, the global robotic welding market is projected to grow from USD 4.32 billion in 2020 to USD 6.51 billion by 2025, highlighting the increasing adoption of automation in the industry. This substantial growth underscores the profound impact that robotic technologies have on enhancing manufacturing capabilities.

The advantages of utilizing robotic welding machines extend beyond mere automation, encompassing improvements in quality, consistency, and safety. A survey conducted by the American Welding Society indicates that over 50% of manufacturers employing robotic welding report significant increases in weld quality and a reduction in production times. Furthermore, robotic systems minimize human exposure to hazardous environments, thereby fostering a safer workplace. As manufacturers strive to meet the demands of a competitive market, understanding the top benefits of robotic welding machines becomes essential for optimizing production processes and achieving sustainable growth.

Overview of Robotic Welding Technology in Manufacturing

Robotic welding technology has revolutionized the landscape of modern manufacturing by enhancing productivity and ensuring high-quality outputs. According to a report by the International Federation of Robotics, the automotive industry alone accounted for over 60% of robot installations in recent years, showcasing the significance of robotic welding in that sector. These advanced systems are equipped with precise sensors and programming capabilities that allow for consistent and accurate welds, which not only reduces the risk of human error but also significantly minimizes waste due to flawed products.

The integration of robotic welding machines also leads to increased operational efficiency. A study conducted by McKinsey & Company highlighted that manufacturing companies that adopted robotic automation witnessed productivity gains of 20-30%. This shift not only accelerates production times but also allows skilled workers to focus on more complex tasks, thereby enhancing overall workplace safety and job satisfaction. Furthermore, as industries face a growing demand for flexible manufacturing and shorter lead times, robotic welding systems adapt quickly to different projects, ultimately leading to a more agile production environment.

Top 10 Benefits of Using Robotic Welding Machines in Modern Manufacturing

| Benefit | Description | Impact |

|---|---|---|

| Increased Efficiency | Robotic welding machines operate continuously, reducing downtime. | Higher output and productivity. |

| Improved Precision | Enhanced accuracy in welding joints and seams. | Consistent quality and reduced defects. |

| Cost Savings | Less material wastage and reduced labor costs. | Lower operational expenses. |

| Enhanced Safety | Robots handle hazardous welding processes, minimizing human exposure. | Reduced workplace injuries. |

| Flexibility | Robots can be reprogrammed for different welding tasks. | Adaptability to various production needs. |

| Higher Weld Quality | Superior control leads to better weld quality. | Improved end-product integrity. |

| Consistency | Uniformity in welds across production runs. | Reliable production standards. |

| Data Collection | Ability to collect and analyze welding data. | Informed decision-making for process improvements. |

| Scalability | Easily scalable to meet demand increases. | Supports business growth and operational expansion. |

| Reduced Lead Times | Faster welding processes shorten overall production time. | Quicker delivery to customers. |

Enhanced Precision and Quality with Robotic Welding Machines

The adoption of robotic welding machines in modern manufacturing has revolutionized the way industries approach precision and quality. According to a report by the International Federation of Robotics, robotic welding has seen a significant annual growth rate of around 10%, a trend driven by the increasing demand for high-quality welds in various sectors such as automotive, aerospace, and construction. Robotic systems are designed to execute repetitive welding tasks with meticulous accuracy, ensuring that each weld meets stringent quality standards. This level of precision minimizes the risk of defects, which is particularly critical in applications where structural integrity is paramount.

Enhanced precision not only leads to improved product quality but also significantly optimizes production efficiency. The American Welding Society has noted that robotic welding can increase productivity by up to 30% compared to traditional methods. This improvement stems from the robots' ability to operate continuously without the fatigue or variability associated with human welders. Additionally, advanced vision systems integrated into these machines allow for real-time adjustments to welding parameters, further enhancing the quality of the finished product. As industries continue to prioritize safety and effectiveness, the efficiency and reliability of robotic welding machines position them as indispensable tools in modern manufacturing environments.

Increased Efficiency and Productivity in Manufacturing Processes

In the fast-evolving landscape of modern manufacturing, robotic welding machines have emerged as a pivotal technology, significantly enhancing efficiency and productivity. These automated systems reduce human error, ensuring precise and consistent welds that improve the overall quality of the products. By automating repetitive tasks, manufacturers can streamline processes, allowing skilled workers to focus on more complex and value-added activities. This shift not only optimizes labor utilization but also accelerates production cycles, meeting increasing market demands with agility.

Moreover, robotic welding machines operate at a speed and consistency unattainable by manual welding techniques. With their ability to maintain optimal weld parameters without fatigue, these machines help minimize downtime and increase throughput. Real-time monitoring and data collection capabilities further enhance productivity by identifying areas for improvement and allowing for proactive adjustments. As a result, manufacturers witness a boost in productivity, leading to shorter lead times and enhanced competitiveness in a challenging market. The integration of robotic welding technology thus serves as a critical factor in driving operational excellence and achieving higher production outputs in modern manufacturing environments.

Top 10 Benefits of Using Robotic Welding Machines in Modern Manufacturing

Reducing Operational Costs through Robotic Welding Solutions

Robotic welding machines are revolutionizing modern manufacturing by significantly reducing operational costs. According to a report by the International Federation of Robotics, companies that have integrated robotic welding solutions see a reduction in labor costs by up to 30%. This reduction is largely attributed to the automation of repetitive tasks, allowing skilled labor to focus on more strategic operations while robots handle high-volume welding processes with accuracy and speed.

Moreover, robotic welding technologies enhance production efficiency and minimize material waste. The Fraunhofer Institute for Production Technology revealed that manufacturers using robotic welding systems typically experience a 25% increase in productivity due to faster cycle times and lower defect rates. This translates into fewer resources spent on rework and repairs, further driving down costs. Additionally, with the increasing precision of robotic systems, the predictable consistency in weld quality reduces the likelihood of expensive production delays, making it a financially savvy choice for firms looking to optimize their operations.

Improved Safety and Working Conditions in Manufacturing Environments

In modern manufacturing, the integration of robotic welding machines has significantly transformed workplace safety and conditions. According to a report by the Occupational Safety and Health Administration (OSHA), workplaces implementing robotic welding technology have seen a 30% reduction in accident rates due to minimized human involvement in hazardous tasks. The precision and consistency of robotic machines not only enhance quality but also reduce the risk of injury from repetitive motion and exposure to harmful fumes associated with traditional welding processes.

One effective strategy for improving safety is to implement rigorous training programs for workers. Workers should be educated on the capabilities and limitations of robotic welding systems to foster collaboration between humans and machines. Moreover, maintaining clear communication about safety protocols and emergency procedures is crucial. Creating a workplace culture that prioritizes safety ensures that employees remain vigilant and proactive.

Additionally, companies should invest in regular maintenance and updates for their robotic systems. A well-maintained machine operates not only efficiently but also safely, as malfunctioning or outdated equipment can pose significant risks. Establishing a scheduled maintenance routine can prevent potential hazards, ensuring that both human workers and robotic systems function seamlessly together, thereby creating a safer manufacturing environment.

Related Posts

-

The Future of Manufacturing How Robotic Welding Machines Are Revolutionizing the Industry

-

The Future of Manufacturing Embracing Robotic Welding Systems and Their Impact on Industry

-

2025 Top 5 Automated Welding Robots Revolutionizing Efficiency with 30% Productivity Increase

-

How to Choose the Right Robotic Welding Cell for Your Manufacturing Needs

-

2025 Top 10 Robotic Welding Automation Trends You Need to Know

-

Revolutionizing Industries with Robotic Systems A Deep Dive into the Future of Automation