Discover the Best Robotic Welding Classes in 2025: Skills for the Future!

As the manufacturing industry continues to evolve, the demand for skilled technicians in advanced technologies is on the rise. Among these, robotic welding represents a significant area of growth, merging automation and craftsmanship to enhance productivity and precision in welding processes. In 2025, the need for trained professionals who can operate and maintain robotic welding systems will be more critical than ever. For those looking to embark on a rewarding career in this field, enrolling in robotic welding classes is a crucial step towards gaining the specialized skills required to thrive.

These classes offer comprehensive training programs designed to equip students with both theoretical knowledge and hands-on experience. Participants will delve into topics such as robotic programming, welding techniques, safety protocols, and equipment maintenance, all of which are essential for mastering the complexities of robotic welding technology. With hands-on training simulations, students can expect to develop the practical skills necessary to handle state-of-the-art welding robots effectively.

In summary, 2025 promises to be a pivotal year for those entering the robotic welding sphere. By taking advantage of available robotic welding classes, aspiring technicians can ensure they are well-prepared for the opportunities and challenges ahead in this dynamic and innovative industry. Embrace the future of welding and position yourself at the forefront of technological advancement!

Overview of Robotic Welding and Its Importance in Modern Industry

Robotic welding has emerged as a cornerstone of modern manufacturing, revolutionizing the way industries approach metal fabrication and assembly. This automated process employs advanced robotic systems to perform welding tasks, enhancing precision, speed, and efficiency. As production demands increase, the ability to integrate robotic welding into workflows has become paramount for companies seeking to maintain competitiveness. By utilizing these sophisticated technologies, manufacturers can reduce labor costs, minimize human error, and significantly boost output while ensuring consistent quality across products.

The importance of robotic welding in modern industry extends beyond mere efficiency. It plays a crucial role in maintaining safety in hazardous work environments, reducing worker exposure to harmful conditions associated with traditional welding. Additionally, the adaptability of robotic systems allows for quick changes in production lines, enabling manufacturers to pivot rapidly in response to market trends or consumer demands.

As industries evolve, understanding and mastering the skills associated with robotic welding will be vital for those entering the workforce, positioning them favorably in a landscape increasingly dominated by automation and digital technologies.

Key Skills and Competencies Required for Robotic Welding Professionals

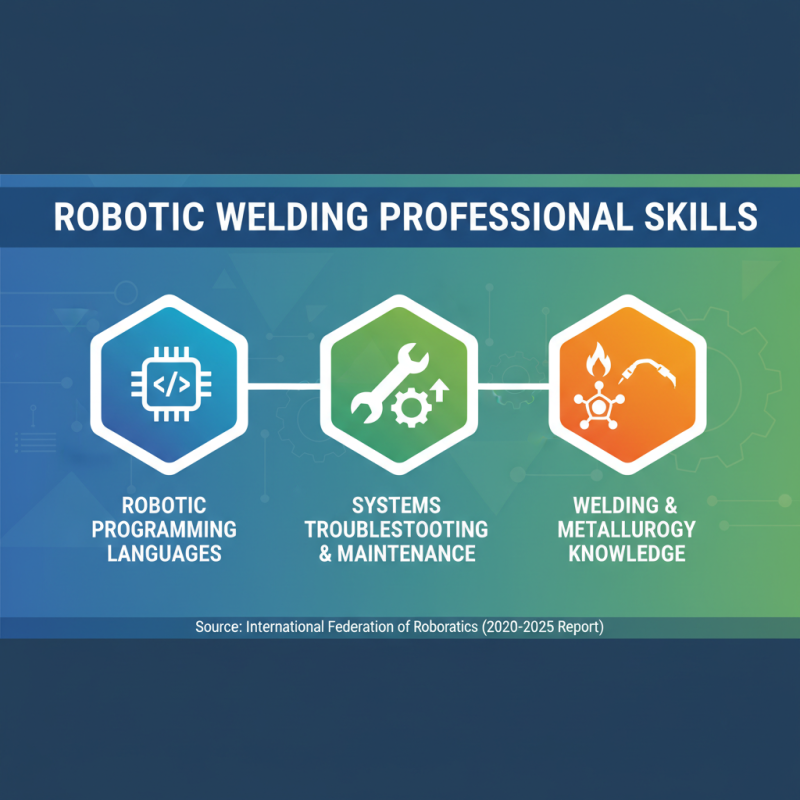

As the demand for automation in manufacturing continues to rise, the skills required for robotic welding professionals are becoming increasingly critical. According to a report from the International Federation of Robotics, the global market for industrial robots is expected to grow at a CAGR of 26% from 2020 to 2025. Consequently, aspiring robotic welding technicians need to cultivate a robust skill set that blends technical proficiency with problem-solving abilities. Key competencies include understanding robotic programming languages, the ability to troubleshoot and maintain automated systems, and a foundational knowledge of welding techniques and metallurgy.

Moreover, as industries shift towards a more interconnected and data-driven landscape, professionals must also be adept at using advanced technologies. Skills in data analysis and an understanding of Industry 4.0 concepts are becoming vital, with a study by McKinsey indicating that 70% of organizations will adopt some form of automation by 2025. This transition will demand robotic welders who can interpret data to improve efficiency and productivity while ensuring that safety standards are maintained. Continuous learning and adaptability will be crucial, as technological advancements will necessitate ongoing skill development in this fast-evolving field.

Top Institutions Offering Robotic Welding Classes in 2025

As the demand for skilled professionals in robotic welding continues to rise, institutions across the globe are stepping up to meet this challenge. In 2025, numerous educational establishments are offering specialized robotic welding classes designed to equip students with essential skills for this advanced field. According to the Robotics Industries Association, the robotic welding market is expected to grow substantially, with a projected compound annual growth rate (CAGR) of 10% over the next five years. This surge emphasizes the necessity for individuals to undergo formal training in advanced robotics and welding technologies.

Leading institutions are recognizing the importance of modernizing their curricula to include hands-on training and theoretical knowledge in robotic welding. Programs typically cover areas such as automation processes, welding techniques, and the integration of robotics in industrial applications. For example, many vocational schools and technical colleges are collaborating with industry partners to ensure their programs are aligned with the latest technological advancements. This collaboration not only enhances the quality of education but also offers students valuable networking opportunities. As industries increasingly adopt automated solutions, graduates from these robotic welding classes will be well-equipped to tackle the challenges of tomorrow's workforce.

Emerging Technologies and Trends in Robotic Welding Education

The field of robotic welding is evolving rapidly, with emerging technologies shaping the landscape of education in this critical area. As industries increasingly adopt automation, the integration of artificial intelligence (AI) and machine learning into robotic welding processes has become a focal point. These advancements provide students with hands-on experience operating sophisticated systems that can adapt and improve over time, creating a demand for specialized training programs that emphasize these technologies. Robotics education now incorporates modules focusing on programming, maintenance, and troubleshooting of intelligent welding systems, ensuring that future welders are well-equipped for the challenges they will encounter in the workforce.

Additionally, trends in virtual and augmented reality (VR/AR) are revolutionizing the way skills are taught in robotic welding. By simulating real-world welding scenarios, these technologies offer immersive learning experiences that enhance understanding and retention of complex concepts. Students can practice welding techniques in a safe, controlled environment, gaining familiarity with the machinery and workflows before stepping into a physical setting. Institutions are increasingly adopting these innovative educational tools, marking a significant shift towards a more interactive and engaging approach to learning robotic welding. This evolution not only prepares students for existing roles but also fosters a mindset adaptable to future advancements in the industry.

Robotic Welding Skills Demand by Year

Career Opportunities After Completing Robotic Welding Training

Robotic welding training opens doors to a variety of career opportunities in the manufacturing and automotive industries. As companies increasingly adopt automation technologies, the demand for skilled robotic welders continues to rise. Graduating from a robotic welding program equips individuals with advanced skills in operating and programming robotic systems, making them highly sought after by employers. Graduates can find roles as robotics technicians, weld engineers, or automated manufacturing specialists, where they can leverage their training to enhance production efficiency and quality.

Tips for those considering a career in robotic welding include focusing on building a strong foundation in basic welding principles before diving into robotic systems. Understanding traditional welding methods will provide insight into how automation can improve processes. Additionally, seek programs that offer hands-on experience with state-of-the-art robotic systems, as practical skills are crucial in this field. Networking with industry professionals through internships or workshops can also lead to job opportunities post-training, as connections in the sector can significantly enhance your career prospects.

Moreover, staying updated with the latest advancements in welding technology and certifications can further boost employability. Continuous learning ensures that you remain competitive in a rapidly evolving industry. Engage with online communities or forums specifically focused on robotic welding to exchange knowledge and gain insights into emerging trends and job openings. These strategies will not only prepare you for a successful career but also position you as a valuable asset in the workforce.

Discover the Best Robotic Welding Classes in 2025: Skills for the Future!

| Program Name | Duration | Location | Certification Offered | Career Opportunities |

|---|---|---|---|---|

| Intro to Robotic Welding | 6 weeks | Online | Certificate of Completion | Entry-level Welder, CAD Technician |

| Advanced Robotic Welding Techniques | 8 weeks | Community College | Industry-recognized Certification | Robotic Welding Specialist, Maintenance Technician |

| Robotic Welding for Automation | 12 weeks | Hybrid (Online & In-person) | Diploma | Automation Engineer, Robotics Programmer |

| Certified Robotic Welding Technician | 16 weeks | Vocational Institute | National Certification | Senior Welder, Robotics Systems Integrator |

Related Posts

-

Top 10 Robotic Welding Classes to Enhance Your Skills in 2023

-

How to Choose the Best Robotic Welding Classes for Your Career Success

-

How to Start Successful Robotics Projects for Beginners in 2025

-

Revolutionizing Manufacturing: The Impact of Automated Welding Cells on Production Efficiency

-

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

-

How to Choose the Right Robot Machine for Your Business Needs