10 Best Robotics and Automation Solutions Transforming Industries Today

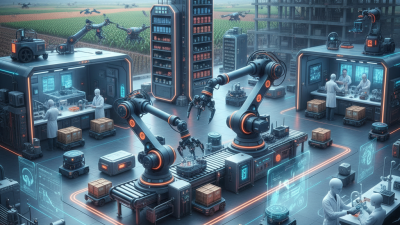

In today's rapidly evolving industrial landscape, the integration of robotics and automation solutions is reshaping the way businesses operate. According to Dr. Rajesh Gupta, a leading expert in robotics and automation, "The future of industry lies in seamless collaboration between humans and machines, enhancing productivity and driving innovation." As industries across various sectors adopt advanced robotic technologies, the impact is profound, revolutionizing processes and improving efficiency.

This article explores the top five cutting-edge robotics and automation solutions that are currently transforming industries. From manufacturing to healthcare, these innovations not only increase operational capabilities but also reduce costs and improve safety. With the convergence of artificial intelligence and robotics, companies are harnessing the power of automation to meet the demands of a competitive market.

As we delve into the most effective solutions in the field of robotics and automation, it becomes evident that these technologies are not merely tools but transformative forces that are redefining industry standards. The insights shared in this piece will provide a glimpse into the future landscape of business operations, emphasizing the crucial role that robotics and automation will play in driving success.

Revolutionizing Manufacturing: The Role of AI-Powered Robotics in Production Lines

Artificial Intelligence (AI) is at the forefront of revolutionizing manufacturing processes, significantly enhancing production lines through advanced robotics. The integration of AI-driven technologies and humanoid robots is transforming traditional manufacturing methods. For instance, China is leading the charge by deploying these sophisticated robots in factories, which has drastically improved operational efficiency. These robots not only automate labor-intensive tasks but also adapt to changing production demands, allowing for a more flexible manufacturing approach.

Meanwhile, developments in collaborative robots, or cobots, are reshaping flexible manufacturing environments, enabling seamless integration with human workers. AI technologies empower these cobots to learn and adapt on the job, which enhances productivity and safety. Additionally, innovations such as AI-driven vision systems and automated guided vehicles are streamlining pack assembly processes, ensuring higher accuracy and speed in production. The collective impact of AI and robotics is driving a new era in manufacturing, characterized by enhanced efficiency, adaptability, and innovation.

10 Best Robotics and Automation Solutions Transforming Industries Today

| Solution Type | Key Features | Industries Affected | Benefits |

|---|---|---|---|

| Collaborative Robots (Cobots) | Easy integration, built-in safety sensors | Manufacturing, Electronics | Increased productivity, reduced labor costs |

| Automated Guided Vehicles (AGVs) | Navigation systems, load transport | Warehousing, Logistics | Efficiency in material handling, reduced manual labor |

| Robotic Process Automation (RPA) | Software robots, process automation | Finance, HR | Cost reduction, faster processing times |

| Industrial Robots | High precision, programmable motion | Automotive, Aerospace | Boosted production rates, improved quality |

| Drones | Aerial surveillance, data collection | Agriculture, Construction | Enhanced data analytics, cost savings |

| 3D Printing Robots | Additive manufacturing, custom design | Healthcare, Aerospace | Rapid prototyping, waste reduction |

| Automated Inspection Systems | AI-based image recognition, real-time feedback | Manufacturing, Quality Control | Improved product quality, reduced error rates |

| Smart Shelving Systems | Automated restocking, inventory tracking | Retail, Warehousing | Optimized inventory management, improved efficiency |

| Predictive Maintenance Systems | Data analytics, sensor monitoring | Manufacturing, Energy | Reduced downtime, extended equipment life |

| Artificial Intelligence (AI) in Robotics | Machine learning, adaptive algorithms | Manufacturing, Supply Chain | Increased flexibility, improved decision-making |

Smart Automation: Streamlining Logistics and Supply Chain Management

The future of AI in supply chain management is becoming increasingly evident as organizations leverage smart automation to enhance logistics and streamline operations. By integrating advanced AI tools, businesses can address critical challenges such as compliance and risk management in cross-border trade. These technologies automate complex compliance processes, optimize logistics routes, and provide real-time insights, significantly reducing operational risks and improving the overall efficiency of the supply chain.

Emerging startups are pioneering innovative solutions that transform the landscape of logistics and supply chain management. From intelligent change management frameworks that simplify engineering change orders to cutting-edge tools designed for smart ports, these advancements are setting new standards for operational excellence. As industries adopt these technologies, the ability to swiftly adapt to changing market demands will not only enhance productivity but also promote a more resilient supply chain ecosystem.

Healthcare Revolution: Robotics Enhancing Patient Care and Surgical Precision

The healthcare sector is experiencing a remarkable transformation driven by advancements in robotics and automation. Robotic systems are becoming integral to surgical procedures, providing unparalleled precision that enhances patient outcomes. For instance, robotic-assisted surgeries allow surgeons to perform complex operations with minimal invasiveness, resulting in shorter recovery times and reduced risk of complications. These systems provide high-definition 3D visualization and dexterous instrument control, enabling physicians to navigate intricate anatomical structures with confidence.

Beyond the operating room, robotics is also revolutionizing patient care in hospitals. Autonomous robots are being deployed for various tasks such as medication delivery, patient monitoring, and even physical therapy assistance. These innovations free up healthcare professionals from routine tasks, allowing them to focus more on patient interaction and care. Moreover, robotic devices designed for rehabilitation are helping patients recover mobility more efficiently. Overall, the integration of robotics in healthcare is not only enhancing the quality of care but also paving the way for innovative treatment methodologies that prioritize patient safety and satisfaction.

Agricultural Innovations: How Automation is Shaping Modern Farming Practices

Automation is revolutionizing the agricultural sector, leading to increased efficiency and sustainability in farming practices. According to a report by the International Federation of Robotics, the agricultural robot market is anticipated to reach a staggering $20 billion by 2025, highlighting the rapid adoption of automation in this field. Innovations such as autonomous tractors, drone technology, and precision farming techniques are helping farmers optimize their operations while minimizing labor costs and resource waste.

To fully benefit from these advancements, farmers should consider integrating automation technologies into their practices. For instance, utilizing drones for crop monitoring not only saves time but also provides critical data for making informed decisions. Additionally, implementing precision irrigation systems can drastically reduce water usage—up to 50% in some cases—allowing for more sustainable farming methods.

Tip: Start small by incorporating one automation tool at a time into your farming practices, allowing you to assess its impact before making major investments.

Focusing on data analytics can also enhance farm management. According to a recent study by Forbes, farmers using data-driven decisions can improve their productivity by 10-15%. Emphasizing automation and data utilization will not only boost yields but also create a more resilient agricultural industry in the face of climate challenges.

Service Industries Transformed: The Impact of Robotics on Customer Experience and Efficiency

The integration of robotics into service industries is revolutionizing customer experiences and enhancing operational efficiency. According to a report by McKinsey, businesses that adopt robotics can improve their customer service efficiency by up to 30%. Robots are now assisting in various capacities, from automating routine inquiries through chatbots to managing inventory in retail environments. This shift not only streamlines workflows but also allows human employees to focus on providing personalized service, thus boosting overall customer satisfaction.

Moreover, a recent study by Deloitte highlights that 60% of service companies are investing in automation technologies to enhance client interactions. The deployment of robotic process automation (RPA) tools enables organizations to handle repetitive tasks quickly and accurately, reducing waiting times and employee burnout. Customers benefit from faster response times and improved service quality, resulting in a more positive interaction with brands. As service industries continue to adopt robotic solutions, the impact on customer experience and operational efficiency is likely to grow, presenting significant opportunities for those willing to innovate.

Related Posts

-

Revolutionizing Industries with Robotic Systems A Deep Dive into the Future of Automation

-

Exploring the Future of Work with Robotic Automation Solutions

-

Unlocking Efficiency: How Robotic Automation Solutions are Transforming Everyday Business Operations

-

Exploring the Future: Top Robotic Systems to Watch in 2025

-

2025 Top 10 Robotic Automation Solutions Transforming Industries Worldwide

-

Revolutionizing Manufacturing: The Impact of Automated Welding Cells on Production Efficiency