How to Choose the Best Robotic Solutions for Your Business?

Choosing the right robotic solutions can be a game changer for your business. According to Dr. Emily Chen, a leading expert in automation, "The key is to tailor robotic solutions to specific business needs." This insight highlights the importance of understanding how robotics can improve efficiency and productivity.

In a world where technology is rapidly evolving, businesses face challenges. Selecting the right robotic tools requires careful consideration. It’s not just about adopting the latest technology; it's about aligning with your operational goals. Many organizations rush into decisions without clear objectives, often resulting in wasted resources.

Defining your needs is crucial before diving into the market. Not every robotic solution will fit every business model. A thoughtful approach includes evaluating current workflows and identifying pain points. Implementing robotic solutions should enhance your operations, not complicate them further. Reflecting on these aspects can lead to a more effective adoption strategy.

Understanding Your Business Needs for Robotic Solutions

When considering robotic solutions, understanding your business needs is crucial. A recent report by McKinsey indicates that automation could boost productivity by 40% in certain sectors. Identify areas where repetitive tasks hinder efficiency. Some businesses still rely heavily on manual processes.

Examine your workflow. Are employees spending too much time on low-value tasks? A survey by Deloitte shows that 61% of businesses struggle with workflow inefficiencies. Addressing these issues can guide your robotic solutions selection. Create a clear picture of the tasks that need improvement. Use this data to measure potential gains.

Consider the integration challenges. Not all robotic solutions fit seamlessly into existing systems. The International Federation of Robotics notes that misaligned expectations can lead to a 30% failure rate in robotic implementations. It’s essential to assess compatibility and ensure your team is prepared for the transition. Avoid rushing the decision; a thoughtful approach yields better outcomes.

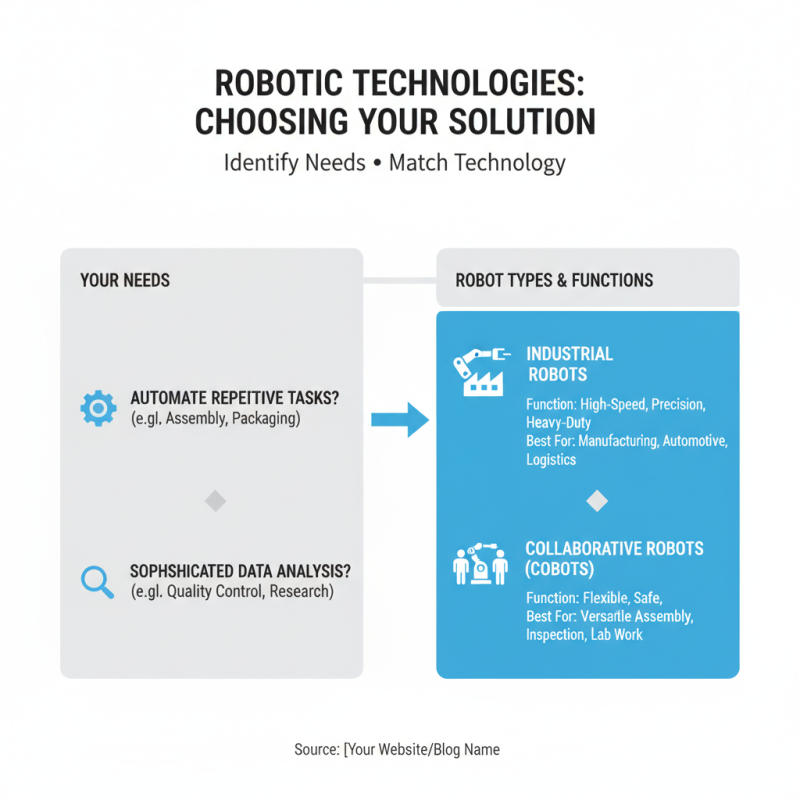

Evaluating Different Types of Robotic Technologies

When evaluating different types of robotic technologies, start by identifying your specific needs. Are you looking to automate repetitive tasks? Or do you need sophisticated solutions for data analysis? Each type of robot serves unique functions. For example, industrial robots excel in manufacturing. Collaborative robots, or cobots, work alongside humans for versatile applications.

Tips: Focus on ease of integration. A robot should fit smoothly into your existing workflows. Look for technologies that offer scalability. As your business grows, your robotic needs may change. Flexibility is key, and you might find that a one-size-fits-all solution doesn't always work.

Consider the learning curve as well. Some robotic systems require extensive training, while others are user-friendly. Spending time on training can be a barrier. On the other hand, simple solutions might not perform complex tasks. Reflect on whether you want immediate functionality or long-term capabilities. Evaluate the balance between these factors to find the best fit for your operations.

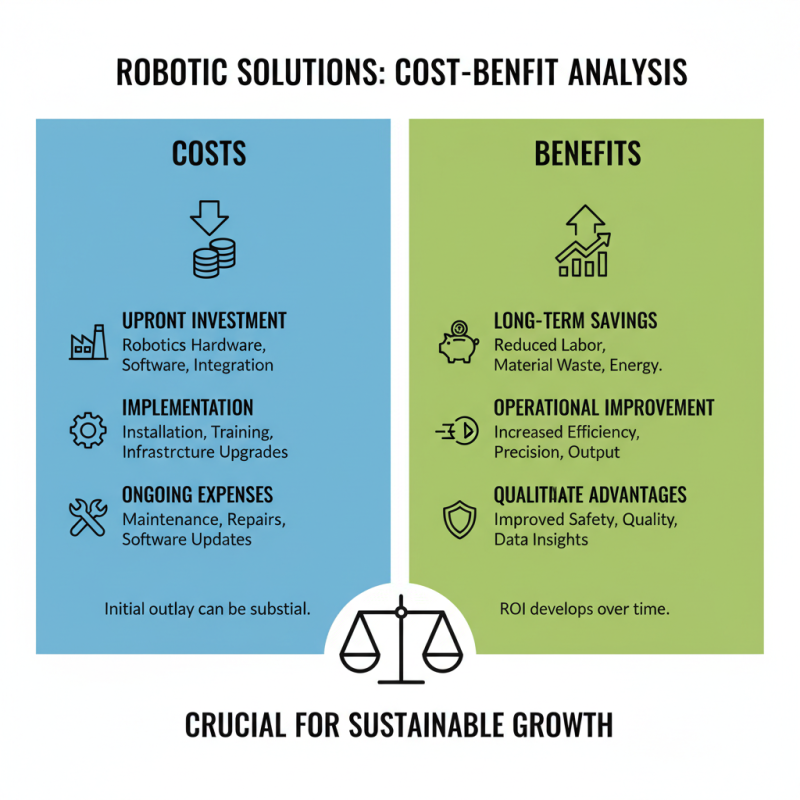

Analyzing Cost vs. Benefit for Implementation

When considering robotic solutions, cost and benefit analysis is crucial. You need to assess not only the upfront costs but also long-term savings. Implementation costs can add up quickly. Installation, training, and maintenance are key factors. These aspects often require a considerable investment, which may not yield immediate returns.

It’s important to project realistic outcomes. For example, consider how automation could reduce labor costs. However, realize that workers may need to adapt. Transitioning from human-operated processes to robotic ones can be challenging. There might be resistance from staff. This conflict can impact productivity during the adjustment period.

Analyzing efficiency gains is also vital. Will robots enhance throughput? Can they operate more consistently than humans? You may find that while automation improves speed, it doesn't always boost quality. If robotic solutions fail to integrate smoothly, you might face setbacks. Reflecting on these potential pitfalls is essential for making informed decisions.

Considering Integration with Existing Systems

When considering robotic solutions for your business, integration with existing systems is crucial. Many businesses overlook this aspect. They may buy the latest technology, but if it doesn’t mesh well with current operations, it could lead to chaos. For instance, an advanced robotic arm might fail to connect with your inventory management software. This can cause delays and inventory errors.

A proper assessment of your existing systems is necessary. Look for gaps that could hinder smooth operation. Are your data formats compatible? Does your network have the capacity? A mismatch here might mean extra costs or even project failure. Sometimes, robots will require extensive retraining of staff. That’s another factor to weigh carefully.

Test integrations on a small scale before full deployment. A pilot project can reveal unforeseen challenges. Ensure you allocate time for adjustments. Feedback from your teams can highlight issues that you might miss. Integration should not feel like an afterthought. Instead, it should be seen as a critical part of choosing robotic solutions.

Assessing Vendor Support and Maintenance Options

When choosing robotic solutions for your business, vendor support and maintenance options are crucial. Recent industry data indicates that 70% of businesses list support as a top priority when selecting technology partners. Without reliable support, even the best robots can underperform. Frequent breakdowns lead to added costs and lost productivity.

Effective maintenance services enhance robotic performance and extend equipment lifespan. Some businesses report that regular maintenance can improve efficiency by up to 30%. Yet, many vendors do not offer comprehensive support packages. This lack can be a red flag, especially for those new to robotics.

Companies need to consider their specific needs. What happens when a robot malfunctions? How quickly can a vendor respond? Lack of timely support can hinder operations significantly. In an increasingly automated world, having a solid maintenance plan is no longer optional. It's essential.

How to Choose the Best Robotic Solutions for Your Business? - Assessing Vendor Support and Maintenance Options

| Vendor | Support Options | Maintenance Frequency | Response Time | Customer Satisfaction Rating |

|---|---|---|---|---|

| Vendor A | 24/7 Phone and Email Support | Monthly | 1 Hour | 4.8/5 |

| Vendor B | Email Support and Live Chat | Every 6 Weeks | 2 Hours | 4.2/5 |

| Vendor C | On-Site Support Available | Quarterly | 3 Hours | 4.5/5 |

| Vendor D | Online Resource Center | Biannual | 5 Hours | 4.0/5 |

| Vendor E | Dedicated Account Manager | Monthly | 30 Minutes | 4.9/5 |

Related Posts

-

Exploring the Future: Top Robotic Systems to Watch in 2025

-

How to Start Successful Robotics Projects for Beginners in 2025

-

Unlocking Efficiency: How Robotic Automation Solutions are Transforming Everyday Business Operations

-

Exploring the Future of Work with Robotic Automation Solutions

-

Revolutionizing Industries with Robotic Systems A Deep Dive into the Future of Automation

-

2025 Top 10 Robotic Automation Solutions Transforming Industries Worldwide