How to Choose the Best Robotic Welding Classes for Your Career Success

In the rapidly evolving field of manufacturing, the demand for skilled professionals who can operate advanced technologies such as robotic welding is surging. According to industry expert Dr. Emily Carter, a leading authority on automation in welding, "The right training in robotic welding classes can set the foundation for a successful and rewarding career." Aspiring welders must recognize the importance of selecting the best training programs to equip themselves with the necessary skills to thrive in this competitive environment.

Choosing the right robotic welding classes is paramount not only for personal growth but also for meeting industry demands. With the integration of robotics in welding processes, having a solid understanding of both the theoretical and practical aspects of the technology is essential. The landscape is filled with various educational opportunities, each promising to enhance your capabilities. It is crucial to evaluate these options based on factors such as curriculum depth, hands-on experience, and instructor expertise, ensuring that the training aligns with your career goals.

As you embark on this journey, remember that the quality of your education can significantly impact your future in the welding industry. Emphasizing the importance of well-structured robotic welding classes will not only prepare you for immediate challenges but also position you for long-term success in an industry that increasingly relies on automation and innovation.

Understanding the Importance of Robotic Welding in Modern Manufacturing

Robotic welding has become a cornerstone of modern manufacturing, transforming the way products are assembled and constructed. With the industry's shift towards automation, the demand for skilled robotic welding professionals continues to rise. This technology not only enhances efficiency and precision but also allows for greater flexibility in production. By integrating advanced robotics into welding processes, manufacturers can significantly reduce operational costs while increasing output rates, making it crucial for businesses to adopt these innovations to stay competitive.

Furthermore, robotic welding plays a vital role in maintaining quality control throughout the manufacturing cycle. Unlike traditional welding methods, robotic systems can replicate exact movements with unwavering consistency, minimizing human error. This level of accuracy ensures that the final products meet stringent quality standards, bolstering both safety and reliability. As industries evolve, understanding and mastering robotic welding techniques will be essential for those seeking to advance their careers in manufacturing, ensuring that they remain at the forefront of technological advancements and industrial growth.

Key Factors to Consider When Selecting Welding Classes

When selecting robotic welding classes for career advancement, it's crucial to consider factors that align with industry needs. According to the American Welding Society (AWS), the demand for skilled welders is expected to grow by 6% from 2020 to 2030. This statistic underscores the importance of choosing a program that not only covers fundamental welding techniques but also emphasizes the integration of robotic automation. As automation becomes more prevalent in manufacturing, training that incorporates hands-on experience with modern robotic systems is invaluable for future job opportunities.

In addition to curriculum content, prospective students should evaluate the qualifications of the instructors. Industry professionals with years of experience in both traditional and robotic welding can provide insights that enrich the learning experience. Research shows that programs led by experienced practitioners result in higher student satisfaction and better job placement opportunities. Furthermore, accreditation of the institution plays a significant role in ensuring that the education received meets industry standards, which can enhance the value of the certification obtained upon completion of the course. Such credentials are increasingly important in a competitive job market where employers seek evidence of formal training and expertise.

Evaluating the facility's resources is also vital. Access to modern welding equipment and technology can significantly enhance the quality of education. A 2021 report from the Fabricators & Manufacturers Association highlights that programs with modern facilities produce graduates who are more proficient and better prepared to tackle real-world challenges. Therefore, considering these factors will not only aid in selecting the right program but will ultimately contribute to a successful career in robotic welding.

Comparing Different Types of Robotic Welding Training Programs

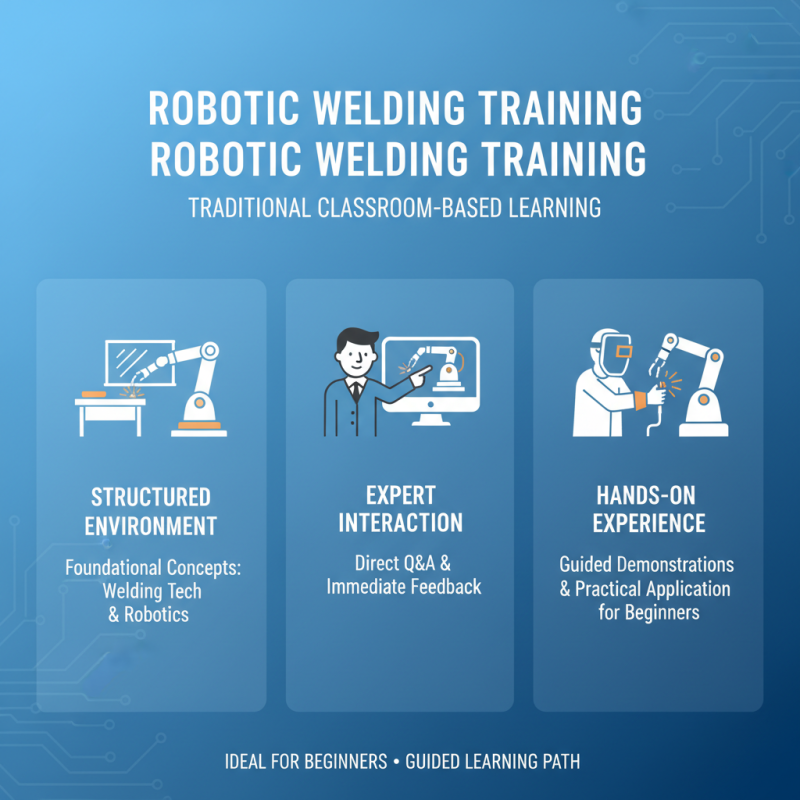

When it comes to robotic welding training programs, it's essential to understand the different types available to make an informed decision. Traditional classroom-based learning offers a structured environment with direct interaction with instructors, allowing students to ask questions and receive immediate feedback. This approach often covers foundational concepts in welding technology and robotics while providing hands-on demonstrations. Such programs can be ideal for beginners who benefit from a guided learning experience.

On the other hand, online training programs have surged in popularity due to their flexibility. Many professionals prefer this option as it allows them to learn at their own pace, fitting their education around work and personal commitments. Online courses often provide video tutorials, interactive simulations, and assessments, enabling students to grasp complex welding concepts and practice problem-solving skills effectively. Furthermore, some programs offer virtual labs that simulate real-world welding environments, giving learners the chance to hone their practical skills without the constraints of physical access to equipment.

Lastly, hybrid training programs combine elements of both traditional and online formats. These typically involve hands-on sessions in a workshop complemented by online theoretical courses. This blended approach can provide the best of both worlds, allowing students to benefit from face-to-face mentorship while also enjoying the flexibility of online resources. By evaluating the characteristics of each program type, individuals can select the one that aligns best with their learning style and career aspirations in the field of robotic welding.

Evaluating Instructors and Course Content for Quality Education

When selecting robotic welding classes, a primary consideration is the quality of instructors and the course content. Research indicates that experienced instructors significantly enhance educational outcomes. According to a report by the American Welding Society, 70% of successful welders credit their success to having knowledgeable and skilled mentors during their training. Engaging instructors who not only teach theory but also share real-world applications and experiences can bridge the gap between academic learning and practical skills.

Additionally, evaluating the course content is crucial for ensuring a thorough educational experience. A robust curriculum should encompass both the fundamentals of welding techniques and the technological advancements in robotic systems. Industry reports suggest that as automation in welding increases, with a projected growth rate of 8.2% annually through 2025, courses must adapt to incorporate new tools and methodologies that align with current market demands. This allows students to stay relevant and competitive in a rapidly evolving field. Opting for programs that include hands-on training and project-based learning further prepares students for the complexities of modern welding environments.

Comparison of Key Factors for Choosing Robotic Welding Classes

Exploring Certification Opportunities for Career Advancement in Welding

When considering a career in robotic welding, pursuing relevant certifications can significantly enhance your professional status and open doors to advancement opportunities. Certification programs typically offer specialized training in robotic programming, operation, and maintenance, ensuring that you are well-versed in the latest technologies. These programs often include hands-on experiences, allowing you to apply theoretical knowledge in a practical setting, which is essential for building confidence and competence in the field.

Gaining certification not only equips you with critical skills but also provides you with a competitive edge in the job market. Many employers seek certified welders, as they demonstrate a commitment to professional development and a thorough understanding of robotic systems. By exploring various certification options, you can tailor your educational path to meet specific industry needs, making you a more attractive candidate for positions in manufacturing and production environments. Additionally, many certification programs also offer networking opportunities with industry professionals, facilitating valuable connections that can further boost your career trajectory in welding.

How to Choose the Best Robotic Welding Classes for Your Career Success - Exploring Certification Opportunities for Career Advancement in Welding

| Course Name | Duration | Certification Offered | Prerequisites | Cost |

|---|---|---|---|---|

| Basic Robotic Welding | 10 weeks | Robotic Welding Technician Certificate | None | $1,200 |

| Advanced Robotic Welding | 8 weeks | Advanced Robotic Welding Certification | Basic Robotic Welding | $1,500 |

| Robotic Welding Programming | 6 weeks | Robotic Programming Certification | Basic Computer Skills | $900 |

| Industry 4.0 in Welding | 5 weeks | Industry 4.0 Certification | Basic Welding Knowledge | $750 |

| Safety in Robotic Welding | 3 weeks | Safety Certification | None | $500 |

Related Posts

-

2025 Top 5 Robotic Welding Classes for Advanced Skills and Career Growth

-

Top 10 Robotic Welding Classes to Enhance Your Skills in 2023

-

5 Essential Tips for Optimizing Robotic Grinding Efficiency: Boost Your Production by 30%

-

Revolutionizing Efficiency: How Robotic Process Automation Solutions Transform Modern Workflows

-

Revolutionizing Industries with Robotic Systems A Deep Dive into the Future of Automation

-

What is a Robotics Technician? Skills, Responsibilities, and Career Path Explained