How to Choose the Right Robot Machine for Your Business Needs

Choosing the right robot machine for your business can be a daunting task, especially with the rapid advancements in technology and the myriad of options available in the market today. To navigate this complex landscape, it is essential to understand not only your specific business needs but also the capabilities and limitations of various robot machines. Dr. Emily Carter, a leading expert in robotics and automation, emphasizes this point by stating, "Selecting the right robot machine is not just about the technology itself, but how well it aligns with your operational goals and enhances your efficiency."

In making this choice, businesses must consider factors such as the types of tasks the robot machine will perform, the integration process with existing systems, and the potential return on investment. With automation transforming industries, having a clear strategy can help in choosing a robot machine that not only meets immediate requirements but also adapts to future challenges. As organizations strive to maintain competitiveness, understanding the nuances of automation technology becomes increasingly vital.

Ultimately, the decision-making process should involve thorough research and a comprehensive assessment of available options. By investing the time to evaluate the right robot machine, businesses can pave the way for increased productivity and innovation, ensuring success in an ever-evolving marketplace.

Determining Your Business Objectives for Robot Implementation

Determining your business objectives is a crucial first step before implementing robotic solutions. To effectively choose the right robotic machine, you need to assess your current operational challenges and define the specific goals you want to achieve. Are you looking to increase production efficiency, reduce labor costs, or improve product quality? By clearly outlining these objectives, you can identify the functions that the robot needs to perform and the areas of your business that will benefit most from automation.

Once you have established your business objectives, it's essential to consider how these goals align with your overall strategic vision. This means evaluating whether the implementation of robots will support long-term growth or merely serve as a short-term solution. For example, if your objective is to enhance customer service through faster delivery times, you might look for machines that effectively integrate with your logistics system. By aligning the capabilities of the robot with your business needs, you set a foundation for not just immediate improvements but also sustainable success in the future.

Evaluating Different Types of Robotics Technology Available Today

When choosing the right robotic technology for your business needs, it is essential to evaluate the various types of robotics solutions available today. According to a recent report by the International Federation of Robotics, the global industrial robot market is expected to grow by 9% annually, reaching a market value of over $70 billion by 2026. This growth is largely driven by advancements in automation, including collaborative robots (cobots) designed to work alongside human operators safely and efficiently. Cobots are particularly beneficial for small and medium enterprises (SMEs) looking to enhance productivity without substantial capital investment.

Another critical area to consider is service robotics, which encompasses a wide range of applications from logistics to healthcare. The World Robotics report highlights a surge in demand for service robots, forecasting a market expansion of over 20% per year. This trend underscores the potential of robotics to optimize operations in various sectors such as delivery automation in retail or robotic-assisted surgeries in healthcare. Evaluating your specific operational requirements, workforce safety, and the technological adaptability of the robotics you consider can significantly impact your success in integrating these systems into your business.

Comparison of Different Types of Robotics Technology

Analyzing Return on Investment (ROI) for Robotic Systems in Industry

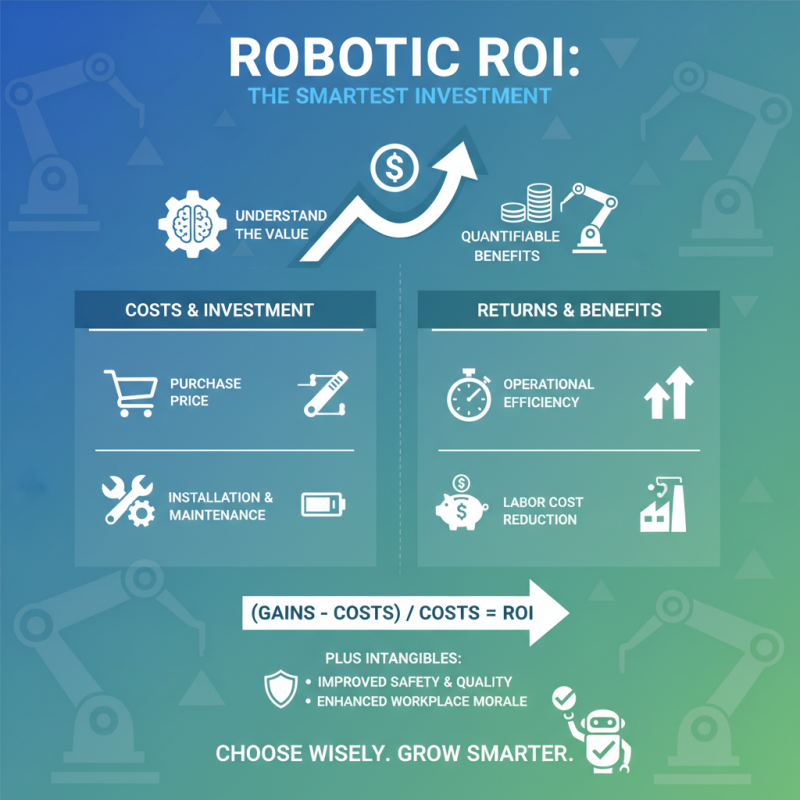

When selecting a robotic machine for your business, understanding the return on investment (ROI) is crucial. ROI provides a quantifiable measure to assess how much value a robotic system can generate in comparison to its initial costs. This assessment goes beyond mere purchase price; it encompasses operational efficiencies, labor cost reductions, and the potential for increased production capacity. A comprehensive ROI analysis should consider not only direct financial returns but also intangible benefits such as improved safety, quality control, and enhanced workplace morale.

To effectively analyze ROI for robotic systems, businesses should gather data on current operational metrics and forecast potential improvements. This includes evaluating downtime reduction, maintenance costs, and the lifespan of the robotic equipment. By creating detailed projections based on these factors, companies can establish a clearer picture of how quickly a robotic investment will pay off. It’s also important to consider the scalability of robotic systems—assessing whether these machines can adapt to future business needs or new market demands can significantly influence long-term ROI. With a thorough understanding of these components, businesses can make informed decisions that align their robotic investments with their operational goals.

Identifying Integration Challenges with Existing Business Processes

When selecting the right robot machine for your business, a crucial step involves identifying potential integration challenges with your existing business processes. Many companies often overlook the importance of assessing how a new robotic solution will fit within their current operational framework. This oversight can lead to disruptions in workflow, increased downtime, and ultimately, unmet expectations regarding return on investment.

To effectively address integration challenges, businesses should conduct a thorough analysis of their existing systems and workflows. This includes mapping out current processes and identifying areas where automation can provide the most value. Engaging with employees who are directly involved in these processes can offer insights into practical considerations and potential roadblocks. Additionally, understanding the compatibility of the new robot machine with existing software, hardware, and workflows is essential to ensure seamless communication and data exchange between systems.

Furthermore, developing a clear plan for training staff and integrating the new technology will help mitigate resistance to change. It's important to create an environment that encourages adaptation and continuous learning, as these factors will significantly influence the success of the robotic implementation. By proactively addressing these challenges, organizations can ensure that the integration of robotic machines enhances productivity and aligns with their overall business objectives.

Assessing Vendor Reliability and Support for Robot Machines

When selecting a robot machine for your business, one crucial factor to consider is the reliability and support offered by the vendor. A dependable vendor not only provides quality machines but also essential after-sales support, ensuring your operations run smoothly. Before making a purchase, research potential vendors to assess their reputation within the industry. Look for customer reviews, request case studies, and check their history in providing service and support.

Tips: Verify that the vendor has a robust support system in place, including customer service availability and technical assistance. Additionally, consider vendors that offer training programs for your staff, ensuring they can operate and maintain the robot machines effectively. Establishing a solid line of communication with the vendor can also enhance your partnership, making it easier to address any issues that may arise after the purchase.

Another vital aspect is the warranty and maintenance options provided. A well-structured warranty can safeguard your investment, while regular maintenance packages can extend the lifecycle of the machine. Make sure to clarify the terms of service and the availability of spare parts, as delays or shortages can disrupt your operational flow significantly.

Tips: Always inquire about the vendor's response time for maintenance and support requests. This information is vital to understanding how quickly you can expect assistance in case of malfunctions or necessary repairs. Ensure that the vendor's support aligns with your business hours and operational needs.

Related Posts

-

2025 Top 5 Robotic Systems Transforming Industries with 50% Efficiency Boost

-

Top 10 Benefits of Using Robotic Welding Machines in Modern Manufacturing

-

2025 Top 5 Automated Welding Robots Revolutionizing Efficiency with 30% Productivity Increase

-

Revolutionizing Manufacturing: The Impact of Automated Welding Cells on Production Efficiency

-

How to Choose the Best Robotics Software for Your Projects

-

Unlocking Efficiency: How Robotic Automation Solutions are Transforming Everyday Business Operations