How to Choose the Right Robotic Welding Cell for Your Manufacturing Needs

In the fast-evolving landscape of manufacturing, selecting the right robotic welding cell is crucial for optimizing efficiency and maintaining competitiveness. According to Dr. Emily Johnson, a leading expert in automation technology, "The choice of a robotic welding cell can dramatically influence not only the quality of the weld but also the overall productivity of the manufacturing process." This emphasizes that the foundations of a successful welding operation rely heavily on the suitability of the selected robotic system.

As manufacturers grapple with increasing demands for precision and speed, understanding the various functionalities and configurations of robotic welding cells becomes essential. Factors such as the size of the workspace, the complexity of the welding tasks, and the integration with existing systems can greatly impact the effectiveness of robotic solutions. Furthermore, the right choice can lead to significant cost savings and improved product quality, making thorough research and expert consultation indispensable for manufacturers looking to enhance their operations.

Ultimately, choosing the right robotic welding cell involves careful consideration of specific manufacturing needs and available technology. By leveraging insights from industry experts, manufacturers can make informed decisions that will drive innovation and success in their welding processes.

Understanding Your Manufacturing Requirements for Robotic Welding

When selecting the right robotic welding cell, understanding your manufacturing requirements is crucial. Begin by assessing the specific welding processes your operations rely on, such as MIG, TIG, or spot welding. Each technique has distinct capabilities and limitations, influencing the type of robotic system you should consider. Additionally, evaluate the materials you typically work with, as different metals and thicknesses may require specialized equipment or settings to achieve optimal weld quality.

It is equally important to analyze your production volume and cycle times. If your manufacturing demands high volume output, you might need a more sophisticated setup with advanced automation features to ensure efficiency and reduce downtime. Conversely, for smaller production runs or custom projects, a more flexible and adaptable robot might be ideal. Integrating these considerations will help ensure that the robotic welding cell you choose aligns perfectly with your operational goals and enhances overall productivity.

Evaluating Different Types of Robotic Welding Cells Available

When evaluating different types of robotic welding cells, it's essential to consider the specific needs of your manufacturing process. Robotic welding cells vary in design, capability, and automation level. For instance, standard robotic arms are suitable for basic welding tasks and can handle a range of materials and joint types. These cells are often favored for their versatility in smaller operations where flexibility is key. However, for high-volume production, dedicated robotic cells designed specifically for certain tasks can greatly enhance efficiency and output.

Another critical factor to consider is the cell configuration. Offline programming cells allow for setup and programming away from the production line, minimizing downtime during operation. On the other hand, in-line systems provide immediate feedback and adjustments, which can enhance precision and reduce errors in real-time. Additionally, assessing the compatibility of these cells with existing manufacturing equipment and workflow is vital. Understanding your current and future production demands, along with the space available, will guide you in selecting a robotic welding cell that aligns with your operational goals.

Robotic Welding Cells Comparison

Key Features to Look for in Robotic Welding Cells

When selecting a robotic welding cell, several key features should be prioritized to ensure the system meets your manufacturing needs effectively. First and foremost is the flexibility of the cell. Look for a system that can accommodate a variety of welding processes and materials, allowing it to adapt to changes in production demands. Additionally, the ability to easily program and reconfigure the cell for different tasks can significantly enhance productivity and reduce downtime.

Another crucial feature is the precision and quality of the welds. A robotic welding cell should be equipped with advanced sensors and control systems that ensure consistent and high-quality welds, minimizing the risk of defects. Integrated monitoring systems that provide real-time feedback can also aid in maintaining welding quality and efficiency. Lastly, consider the cell's safety features, including protective barriers and emergency stop mechanisms, which are vital for protecting workers in a busy manufacturing environment. These considerations will help you choose a robotic welding cell that not only meets your immediate needs but also supports long-term operational goals.

Assessing Compatibility with Existing Manufacturing Systems

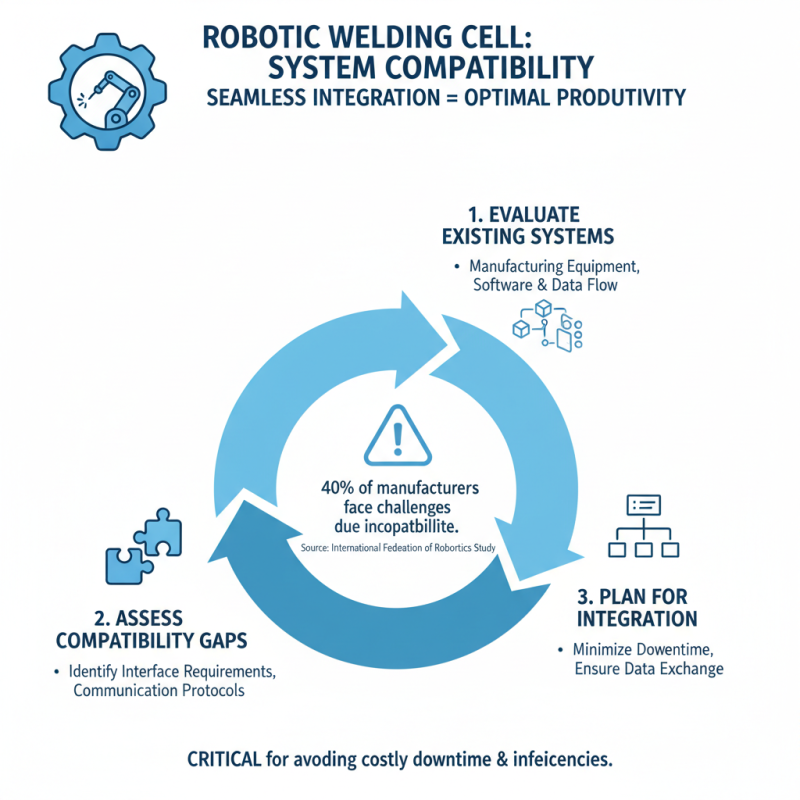

When selecting a robotic welding cell, evaluating its compatibility with existing manufacturing systems is critical for ensuring seamless integration and optimal productivity. According to a study by the International Federation of Robotics, over 40% of manufacturers reported challenges when introducing automation technologies due to incompatibility issues. This highlights the importance of assessing system compatibility to avoid costly downtime and inefficiencies.

Tips for ensuring compatibility include conducting a thorough analysis of your current setup, including machinery specifications, software interfaces, and production workflows. It's advisable to create a comprehensive compatibility checklist that addresses communication protocols, load capacities, and spatial requirements. Furthermore, opting for modular systems can offer greater flexibility, allowing for easier adjustments to accommodate new technologies without significant overhauls.

In addition to hardware considerations, software compatibility must also be prioritized. A report by McKinsey highlights that 80% of manufacturing automation projects face difficulties stemming from mismatched software systems. Ensuring that your robotic welding cell can seamlessly interface with existing manufacturing execution systems will streamline operations and enhance data visibility—enabling better decision-making and resource allocation in your production environment.

Budget Considerations and Return on Investment for Robotic Welding Cells

When selecting a robotic welding cell, budget considerations play a pivotal role in determining the right fit for your manufacturing needs. It is crucial to establish a clear budget that includes not only the initial purchase price of the robotic system but also the associated setup costs, maintenance expenses, and potential training for operators. These factors can significantly impact the overall financial commitment. Companies should conduct a thorough cost analysis to understand how an investment in robotic welding technology can streamline operations and reduce labor costs over time.

Return on investment (ROI) is another vital aspect to evaluate when considering robotic welding cells. Businesses should assess how automation can improve productivity, enhance weld quality, and reduce operation times compared to traditional welding methods. Additionally, ROI can be influenced by the reduction of material waste and the ability to take on more projects due to increased capacity. By carefully analyzing these elements, manufacturers can make informed decisions that align their financial goals with their operational capabilities, ensuring that the chosen robotic welding cell not only fits the budget but also delivers significant long-term value.

How to Choose the Right Robotic Welding Cell for Your Manufacturing Needs

| Feature | Description | Cost Range (USD) | Estimated ROI (Months) |

|---|---|---|---|

| Compact Size | Ideal for facilities with limited floor space. | $50,000 - $80,000 | 6 - 12 |

| High Payload Capacity | Suitable for heavy workpieces up to 300 kg. | $100,000 - $150,000 | 8 - 16 |

| Multi-Process Capability | Welds with MIG, TIG, and Spot processes. | $120,000 - $200,000 | 10 - 18 |

| High Speed Automation | Reduced cycle times for increased productivity. | $80,000 - $120,000 | 5 - 10 |

| User-Friendly Interface | Simplifies programming and operation. | $40,000 - $70,000 | 4 - 8 |

Related Posts

-

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

-

The Future of Manufacturing Embracing Robotic Welding Systems and Their Impact on Industry

-

The Future of Manufacturing How Robotic Welding Machines Are Revolutionizing the Industry

-

Revolutionizing Manufacturing: The Impact of Automated Welding Cells on Production Efficiency

-

Revolutionizing Industries with Robotic Systems A Deep Dive into the Future of Automation

-

Unlocking Efficiency: How Robotic Automation Solutions are Transforming Everyday Business Operations