The Future of Manufacturing Embracing Robotic Welding Systems and Their Impact on Industry

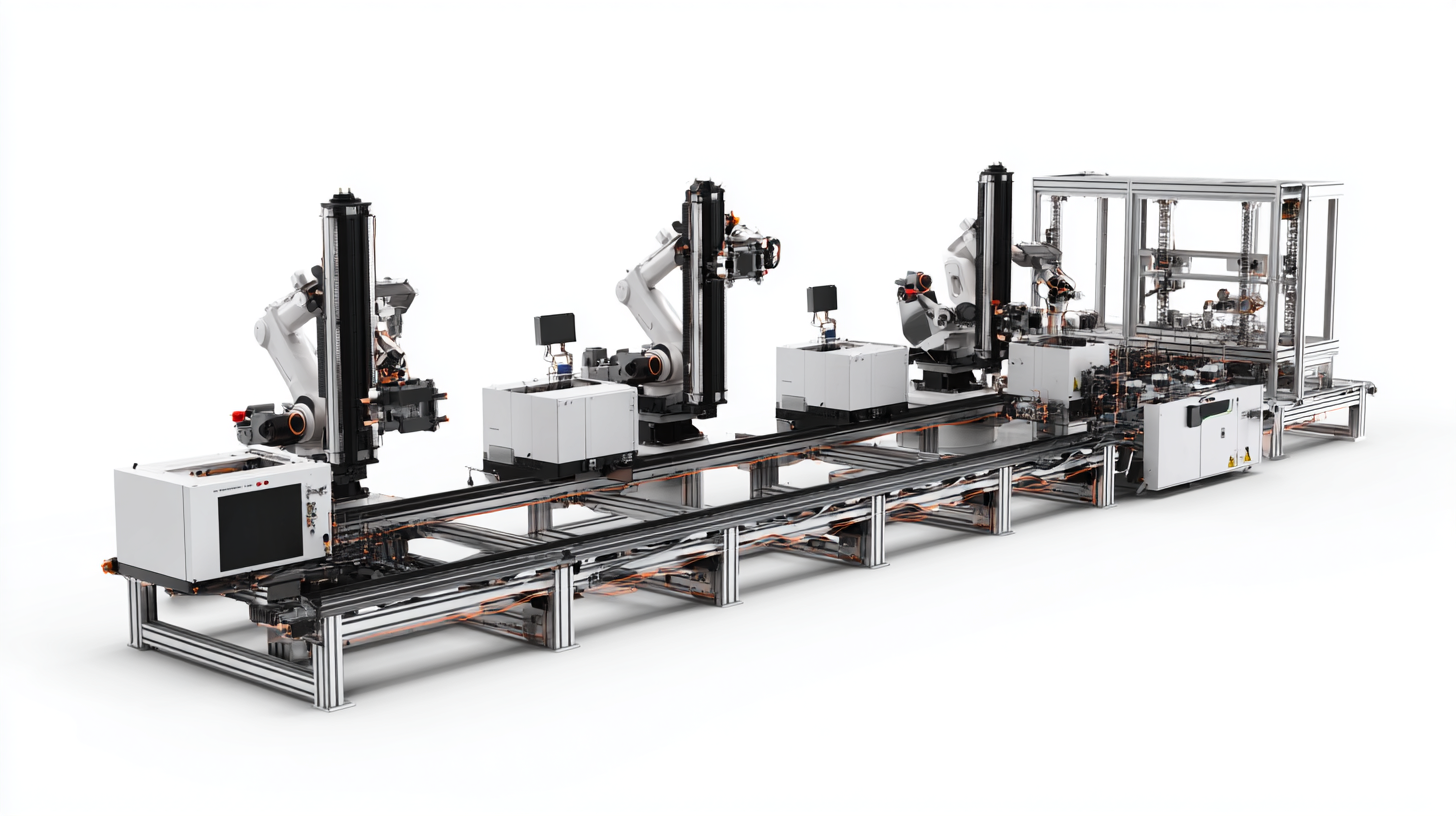

As industries continue to evolve in the face of rapid technological advancements, the integration of robotic welding systems has emerged as a transformative force in modern manufacturing. These automated solutions are not only enhancing precision and efficiency in welding processes but are also reshaping the workforce landscape and redefining operational strategies across various sectors.

In this guide, we will explore the pivotal role of robotic welding systems, examining their benefits, applications, and the substantial impact they have on productivity and safety in the industry. By embracing these innovative technologies, manufacturers can streamline operations, reduce costs, and position themselves competitively in a dynamic market.

Join us as we delve into the future of manufacturing and discover how robotic welding systems are set to revolutionize traditional practices, paving the way for smarter, more agile production environments.

The Rise of Robotic Welding Systems: Transforming the Manufacturing Landscape

The rise of robotic welding systems represents a significant transformation within the manufacturing landscape. As industries strive for increased efficiency and precision, these advanced systems are becoming integral to modern manufacturing processes.

Unlike traditional welding methods, robotic welding systems offer enhanced consistency and quality, minimizing human error and drastically improving production speed. With the ability to operate continuously and tackle complex welding tasks, robots are reshaping the way manufacturers approach their projects, resulting in higher output and reduced labor costs.

Moreover, the integration of robotic welding systems enhances workplace safety. By taking over hazardous tasks, these machines protect human workers from potentially dangerous environments, reducing the risk of workplace injuries.

This shift not only promotes a safer working atmosphere but also allows employees to focus on more complex and value-added operations. As industries increasingly embrace automation and smart technologies, robotic welding systems stand at the forefront of this evolution, paving the way for a new era of manufacturing that aligns with the demands of a rapidly changing economy.

Key Industry Statistics on the Adoption of Robotic Welding Technologies

The adoption of robotic welding technologies is reshaping the manufacturing landscape, with significant implications for various industries. The global market for welding machinery was valued at approximately $15.5 billion in 2024 and is projected to grow to $22.3 billion by 2030, reflecting a compound annual growth rate (CAGR) of 6.3%. This growth is driven by the increasing demand for efficiency and precision in manufacturing processes, particularly in the automotive sector where welding plays a crucial role.

Tips for businesses considering robotic welding systems include assessing the specific needs of their production lines and understanding the range of options available, such as traditional welding robots versus collaborative robots (cobots). It’s essential to evaluate the potential return on investment by calculating the expected gains in productivity and quality. Additionally, keeping up with technological advancements ensures that companies remain competitive in an evolving market.

As industries explore new welding technologies, particularly in shipbuilding and automotive applications, staying informed about the latest developments can provide strategic advantages. Companies should consider how these innovations can improve efficiency and reduce costs, ultimately leading to more sustainable manufacturing practices.

Benefits of Robotic Welding: Efficiency, Quality, and Cost Reduction

The robotic welding industry is witnessing significant growth, driven by its many benefits such as enhanced efficiency, superior quality, and cost reduction. According to recent market analyses, the robotic welding market is projected to increase substantially, with segmentation that highlights the dominance of welding robots and collaborative robots (cobots) across various manufacturing sectors. The automotive industry, in particular, has been a primary driver, capitalizing on robotic welding to improve production rates while maintaining high standards of quality and safety.

Robotic welding systems not only streamline operations but also provide a consistent and precise welding output, minimizing the margin for human error. The efficiency gains are evident, with studies indicating that companies integrating these technologies can see production speeds increase by up to 40%. Furthermore, the cost reduction brought by robotic systems includes lower labor costs and increased material savings due to more accurate welds, which translates to reduced scrap rates. In a rapidly evolving manufacturing landscape, embracing robotic welding technologies becomes essential for companies aiming to remain competitive and meet the growing demands for precision and reliability in production.

Challenges in Implementing Robotic Welding: Skills Gap and Initial Investment

The integration of robotic welding systems in manufacturing presents significant challenges, most notably the skills gap and the requirement for substantial initial investment. As industries pivot towards automation, many workers may find themselves lacking the necessary technical skills to operate and maintain advanced robotic systems. This gap not only affects the efficiency of transitioning to automation but also raises concerns about workforce displacement. Companies must prioritize training programs that equip employees with the skills needed for this technological shift, ensuring that the existing workforce can adapt and thrive alongside new robotics.

Moreover, the initial investment required for implementing robotic welding solutions can be a barrier for many businesses, particularly smaller manufacturers. The costs associated with purchasing robots, along with the expenses related to system integration and employee training, can be daunting. However, it is crucial to view this investment as a long-term strategy that can enhance productivity, lower operating costs, and improve product quality. As manufacturers weigh these challenges against the benefits, it becomes essential to develop a strategic approach that addresses both the skills gap and financial implications, allowing for a smoother transition into the future of manufacturing.

Future Trends: Innovations and Developments in Robotic Welding Systems

The future of manufacturing is being dramatically shaped by advancements in robotic welding systems. As the market for welding equipment is projected to grow from approximately $1.6 billion in 2025 to nearly $2.7 billion by 2033, with a compound annual growth rate of 6.9%, the integration of robotics into welding processes becomes increasingly critical. Innovations in this field are driven by the need for improved efficiency, enhanced precision, and the ability to meet the growing demands of diverse industries.

Companies are emerging as key players, leveraging collaborations and partnerships to push technological boundaries. Innovations such as advanced AI algorithms, energy-efficient designs, and new types of welding robots aimed at various applications—including automotive, aerospace, and electronics—signal a shift towards more intelligent manufacturing solutions. The rise of collaborative robot systems, which can work seamlessly alongside human operators, exemplifies the trend of creating a more flexible and productive industrial environment. As more companies embrace these technologies, the impact on production capabilities and overall industry dynamics will be profound.

Related Posts

-

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

-

Unlocking Efficiency: How Robotic Automation Solutions are Transforming Everyday Business Operations

-

The Future of Manufacturing How Robotic Welding Machines Are Revolutionizing the Industry

-

Exploring the Future of Work with Robotic Automation Solutions

-

Revolutionizing Efficiency: How Robotic Process Automation Solutions Transform Modern Workflows