Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

As industries strive for increased productivity and reduced operational costs, the adoption of robotic welding systems has emerged as a transformative solution within the manufacturing sector. According to a report by the International Federation of Robotics (IFR), the global market for industrial robots is projected to reach $73 billion by 2025, with robotic welding systems seeing significant advancements in technology. These automated solutions not only enhance precision and repeatability in welding processes but also address labor shortages and safety concerns prevalent in the industry. A study conducted by the American Welding Society indicates that companies utilizing robotic welding systems can increase their production rates by up to 30%, drastically lowering cycle times and improving overall efficiency. By integrating these advanced systems, manufacturers can position themselves competitively in a rapidly evolving market, maximizing output while maintaining high-quality standards.

As industries strive for increased productivity and reduced operational costs, the adoption of robotic welding systems has emerged as a transformative solution within the manufacturing sector. According to a report by the International Federation of Robotics (IFR), the global market for industrial robots is projected to reach $73 billion by 2025, with robotic welding systems seeing significant advancements in technology. These automated solutions not only enhance precision and repeatability in welding processes but also address labor shortages and safety concerns prevalent in the industry. A study conducted by the American Welding Society indicates that companies utilizing robotic welding systems can increase their production rates by up to 30%, drastically lowering cycle times and improving overall efficiency. By integrating these advanced systems, manufacturers can position themselves competitively in a rapidly evolving market, maximizing output while maintaining high-quality standards.

Maximizing Production Rates through Smart Robotic Welding Solutions in Manufacturing

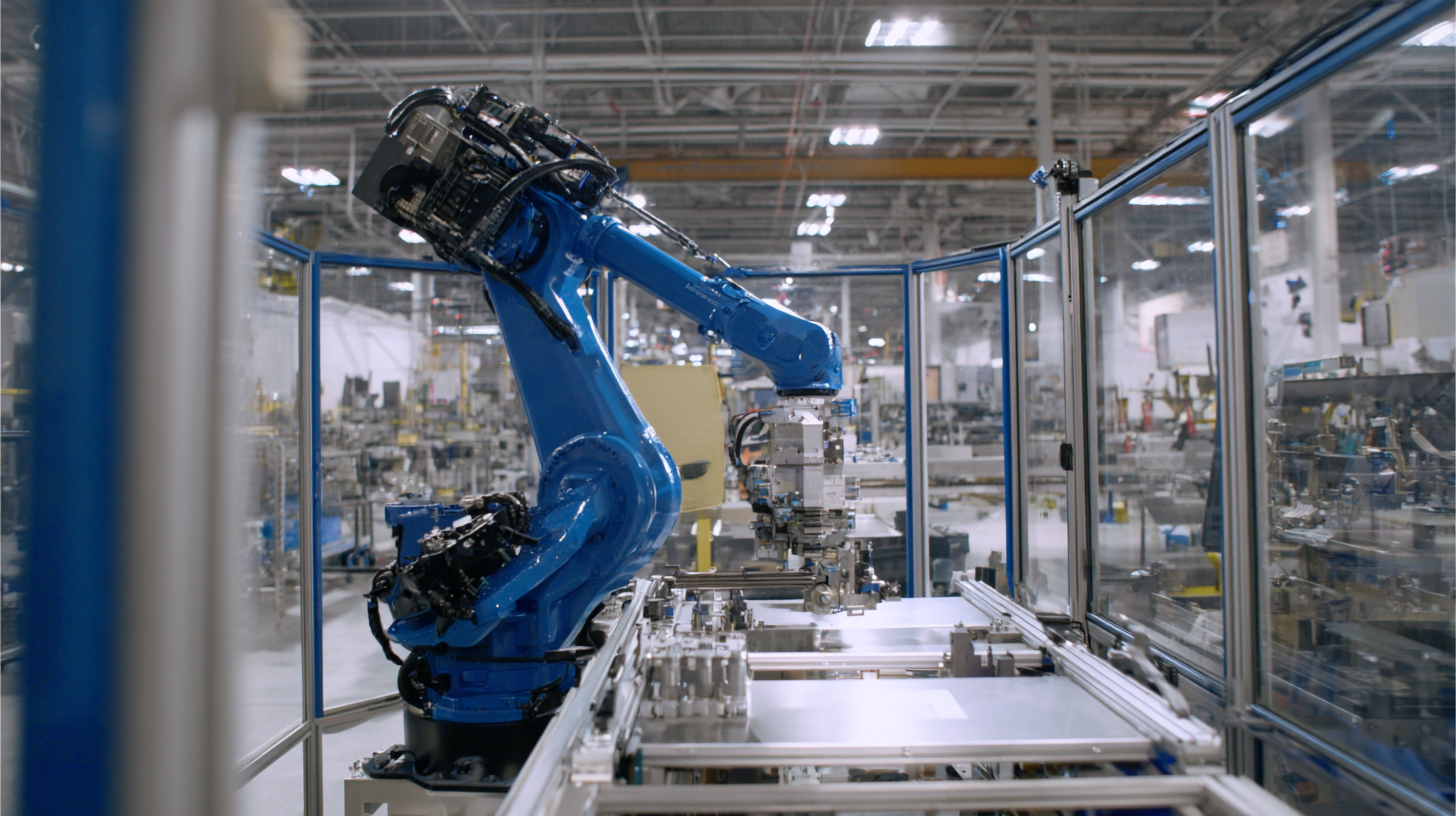

In today's competitive manufacturing landscape, maximizing production rates has become a pivotal challenge, achievable through the integration of smart robotic welding solutions. By leveraging advanced technologies such as artificial intelligence and the Internet of Things, manufacturers are enhancing their welding processes, resulting in remarkable improvements in efficiency and output. These smart systems not only automate repetitive tasks but also provide real-time data analytics, enabling predictive maintenance and reducing downtime.

The automotive industry, in particular, is witnessing a transformation with the adoption of smart welding technologies that streamline production lines. As the demand for electric vehicles grows, robotic welding plays a crucial role in battery assembly, where precision and speed are paramount. By embracing these innovations, manufacturers not only bolster their production rates but also ensure better safety and quality control, thereby positioning themselves at the forefront of Industry 4.0 advancements.

Through these smart welding solutions, the manufacturing sector is redefining productivity and scalability, paving the way for more sustainable industrial practices.

Key Benefits of Integrating Advanced Robotic Welding Systems into Existing Production Lines

Integrating advanced robotic welding systems into existing production lines offers several key benefits that can significantly enhance manufacturing efficiency. Firstly, these systems provide unmatched precision and consistency in welding operations, reducing the likelihood of defects and rework. As a result, companies can achieve higher quality outputs, which not only improves customer satisfaction but also minimizes waste and related costs. The ability to maintain tight tolerances throughout the production process streamlines operations and enhances overall throughput.

Additionally, robotic welding systems can operate continuously with minimal downtime, significantly boosting production rates. Unlike human labor, these robots can work around the clock, increasing output without the need for breaks or shifts. Furthermore, integrating robotics can alleviate workforce shortages, as they can perform repetitive tasks efficiently, allowing human workers to focus on more complex activities that require problem-solving and creativity. This combination of increased speed and reliability positions manufacturers to respond more effectively to market demands and stay competitive in their industries.

Impact of Robotic Welding on Reducing Downtime and Material Waste in Manufacturing

Advanced robotic welding systems play a crucial role in enhancing manufacturing efficiency by significantly reducing downtime and minimizing material waste. The implementation of these systems allows for precise welding processes that operate continuously, which leads to decreased idle time on the production line. Unlike manual welding, which can be subject to human error and inconsistent performance, robotic systems ensure uniformity and speed, thus maintaining a steady workflow. This reliability in operation translates to higher uptime, enabling manufacturers to maximize their output.

Moreover, robotic welding systems are designed with intelligent features that optimize the use of materials. They are capable of adjusting parameters in real-time to reduce excess material use during the welding process, effectively minimizing scrap and waste. This not only lowers material costs but also contributes to a more sustainable production approach. By streamlining the welding operations and implementing precise material handling techniques, manufacturers can achieve a significant reduction in waste, which enhances overall profitability and supports environmental goals.

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

| Metric | Before Implementation | After Implementation | Percentage Improvement |

|---|---|---|---|

| Production Rate (units/hour) | 50 | 75 | 50% |

| Downtime (hours/day) | 4 | 1 | 75% |

| Material Waste (%) | 10 | 3 | 70% |

| Labor Costs (per unit) | $5.00 | $2.50 | 50% |

| Quality Defects (%) | 8 | 2 | 75% |

Leveraging Data Analytics to Optimize Robotic Welding Performance and Efficiency

The role of data analytics in optimizing robotic welding performance is becoming increasingly critical as manufacturers seek to enhance efficiency. By leveraging advanced algorithms and machine learning techniques, production facilities can analyze performance metrics in real time, identifying inefficiencies and suggesting corrective actions. This data-driven approach not only reduces downtime but also improves the quality of welds, ensuring consistent output that meets stringent industry standards.

As the global automotive sector shifts towards lightweight and electric vehicles, the demand for innovative welding solutions is surging. The integration of data analytics into robotic welding systems enables manufacturers to fine-tune their processes for aluminum welding, which is essential for reducing vehicle weight and enhancing battery range. Consequently, companies that embrace these technological advancements position themselves for substantial growth, indicated by the projected expansion of the welding equipment market from $1.596 billion in 2025 to $2.722 billion by 2033, at a compound annual growth rate of 6.9%.

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems

This chart illustrates the production rates and efficiency improvements associated with advanced robotic welding systems over a period of time. The data reflects the impact of leveraging data analytics to optimize robotic welding performance.

Future Trends in Robotic Welding Technologies and Their Potential Impact on Manufacturing Output

The future of robotic welding technologies is poised to revolutionize the manufacturing industry, significantly enhancing production output. As advancements in artificial intelligence and machine learning continue to evolve, modern robotic systems are becoming increasingly capable of adapting to various welding tasks with minimal human intervention. This adaptability allows manufacturers to respond swiftly to changing demands, optimize processes, and reduce downtime, ultimately leading to higher efficiency in production rates.

Furthermore, emerging technologies such as collaborative robots (cobots) are paving the way for safer and more flexible manufacturing environments. These robots can work alongside human operators, sharing tasks and improving overall workflow. The integration of real-time data analytics and IoT connectivity within robotic welding systems also provides manufacturers with valuable insights into their operations, enabling proactive maintenance and operational adjustments that further enhance productivity. As these trends develop, the potential for increased manufacturing output becomes not just a possibility but an impending reality.