Revolutionizing Industries with Robotic Systems A Deep Dive into the Future of Automation

In recent years, industries worldwide have been undergoing a monumental transformation driven by the integration of robotic systems. As automated technologies evolve, they significantly enhance productivity and efficiency across various sectors. According to a report by the International Federation of Robotics, global sales of industrial robots reached a record high of approximately 478,000 units in 2018, a figure that underscores the rapidly growing reliance on automation. This embrace of robotic systems is not merely a trend; it is a fundamental shift that promises to redefine the landscape of manufacturing, logistics, and even healthcare.

In recent years, industries worldwide have been undergoing a monumental transformation driven by the integration of robotic systems. As automated technologies evolve, they significantly enhance productivity and efficiency across various sectors. According to a report by the International Federation of Robotics, global sales of industrial robots reached a record high of approximately 478,000 units in 2018, a figure that underscores the rapidly growing reliance on automation. This embrace of robotic systems is not merely a trend; it is a fundamental shift that promises to redefine the landscape of manufacturing, logistics, and even healthcare.

Expert Dr. Emily Chen, a leading authority in automation technology, emphasizes the impact of robotic systems, stating, "The future of industries relies heavily on the capabilities of robotic systems to drive efficiency and innovation." Her insights reflect a wider consensus among industry leaders who recognize that the adoption of advanced robotics can lead to significant cost reductions and enhanced operational reliability. As we delve into the future of automation, it is clear that the influence of robotic systems will only continue to expand, ushering in a new era of industrial revolution characterized by intelligent, automated processes that redefine how we work and produce.

The Evolution of Robotic Systems: From Concept to Industry Standard

The evolution of robotic systems has undergone remarkable transformations, progressing from early conceptual designs to becoming indispensable across various industries. Initially, robotic systems were primarily utilized in manufacturing for repetitive tasks, but advancements in artificial intelligence and machine learning have propelled their capabilities far beyond these limitations. According to a report by the International Federation of Robotics, global sales of industrial robots reached 384,000 units in 2020, marking a 12% increase from the previous year. Such growth underscores the integration of robotics into critical sectors including automotive, electronics, and consumer goods.

Today, robotic systems are not just augmenting human labor; they are redefining operational standards. The World Economic Forum projected that by 2025, 85 million jobs may be displaced by the shift towards automation, while simultaneously creating 97 million new roles more suited to the new division of labor among humans, machines, and algorithms. As industries continue to adopt robotic solutions for tasks ranging from assembly to logistics, the focus is now shifting toward developing collaborative robots (cobots) that can work alongside humans. This transition illustrates not only the technological advancements in robotics but also the ongoing evolution of workplace dynamics as automation becomes the new industry standard.

Key Industries Impacted by Automation: A Comprehensive Overview

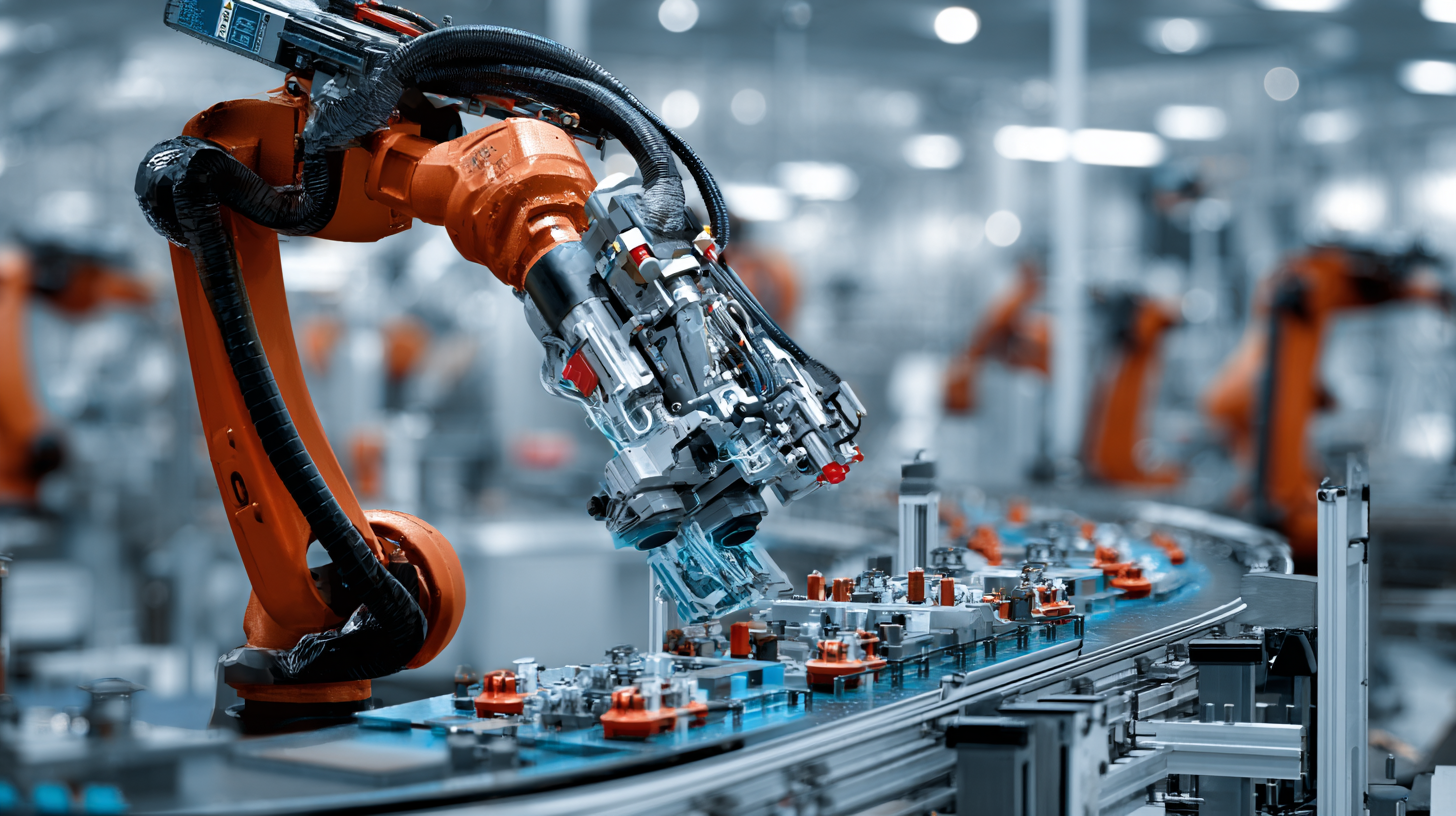

The integration of robotic systems into various industries is transforming traditional processes and increasing efficiency. Manufacturing has been one of the most notable sectors impacted by automation. With robotics taking over repetitive and precise tasks, companies can optimize production lines, reduce human error, and increase output rates. The use of robots for assembly, welding, and quality control has allowed manufacturers to focus more on innovation and product development while streamlining operations.

Healthcare is another industry experiencing a significant shift due to automation. Robotic-assisted surgeries are improving surgical precision and reducing recovery times for patients. Additionally, automated systems in hospitals enhance patient care by managing logistics, such as medication delivery and patient monitoring. This not only streamlines hospital operations but also allows healthcare professionals to dedicate more time to patient interaction, ultimately improving the overall quality of care.

In agriculture, automation is revolutionizing farming practices. Drones and robotic systems are being employed for planting, harvesting, and monitoring crops, which increases yield and reduces the need for manual labor. This technological advancement enables farmers to maximize efficiency while addressing labor shortages, making it a crucial step towards sustainable farming in an increasingly demanding food market.

Revolutionizing Industries with Robotic Systems

This chart illustrates the projected impact of automation across various key industries by the year 2030. The data highlights the percentage of tasks that could be automated, providing insights into how robotic systems are transforming operations.

Innovative Technologies Driving Robotics Forward

Innovative technologies are at the forefront of the robotics revolution, driving industries towards unparalleled efficiency and productivity. Advanced artificial intelligence (AI) is enabling robots to perform complex tasks with increased precision, allowing for better decision-making and adaptability in dynamic environments. Machine learning algorithms empower robots to learn from their experiences, optimizing processes and reducing human intervention. This driving force of AI not only enhances operational efficiency but also opens up new possibilities in sectors such as manufacturing, healthcare, and logistics.

Moreover, cutting-edge sensors and connectivity features are transforming robotics applications. The integration of IoT (Internet of Things) technologies allows robots to communicate with each other and with the broader operational ecosystem. This interconnectedness is crucial for the development of smart factories, where robots can coordinate seamlessly to manage supply chains, monitor equipment health, and respond to real-time data. As these innovative technologies continue to evolve, they hold the potential to redefine industry standards and create a future where robotics plays a central role in automation.

The Role of AI in Enhancing Robotic Efficiency and Adaptability

The integration of artificial intelligence (AI) into robotic systems is transforming industries, enhancing their efficiency and adaptability. According to a recent market report, the global AI robotics market is projected to reach $153 billion by 2027, driven by advancements in

machine learning, natural language processing, computer vision, and contextual awareness. These technologies play a critical role in equipping robots with the ability to learn from their environments, improve decision-making processes, and interact more naturally with human operators.

In terms of applications, industrial robots are set to dominate the market, accounting for over 60% of the total share. Service robots, contributing significantly to sectors like healthcare and logistics, will also see substantial growth as AI continues to refine their capabilities. The synergy between large AI models, retrieval-augmented generation (RAG), and agent-based frameworks enables a new era of robotic sophistication. By combining these elements, businesses can enhance real-time data processing, contextual understanding, and overall operational effectiveness, which are crucial for meeting the demands of an increasingly automated future.

Future Trends: What to Expect in the Next Decade of Automation

As we look ahead to the next decade, the landscape of automation is poised for transformative changes that will redefine industries worldwide. Advancements in artificial intelligence, machine learning, and robotics will create more sophisticated automated systems capable of performing complex tasks with minimal human intervention. This surge in technology will not only enhance productivity but also lead to significant improvements in precision and efficiency across various sectors, from manufacturing to healthcare.

Moreover, the integration of Internet of Things (IoT) devices will enable real-time data exchange between machines, fostering seamless communication and coordination. This interconnectedness will facilitate predictive maintenance, reducing downtime and operational costs. As industries adapt to these emerging technologies, we can expect a shift in workforce dynamics, where jobs will evolve and new skill sets will be in demand.

Employees will increasingly collaborate with robotic systems, focusing on tasks that require creativity and critical thinking, while automation handles repetitive work. This collaborative future promises to maximize human potential while driving unprecedented growth in automation.

Related Posts

-

Exploring the Future of Work with Robotic Automation Solutions

-

Unlocking Efficiency: How Robotic Automation Solutions are Transforming Everyday Business Operations

-

The Future of Manufacturing Embracing Robotic Welding Systems and Their Impact on Industry

-

The Future of Manufacturing How Robotic Welding Machines Are Revolutionizing the Industry

-

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

-

Revolutionizing Efficiency: How Robotic Process Automation Solutions Transform Modern Workflows