5 Essential Tips for Optimizing Robotic Grinding Efficiency: Boost Your Production by 30%

In the ever-evolving landscape of manufacturing, robotic grinding has emerged as a game-changer, significantly enhancing operational efficiency and productivity. Industry expert Dr. Alice Thompson, a leading authority on automation technologies, emphasizes that "embracing robotic grinding can lead to substantial improvements in throughput and precision." As businesses strive to remain competitive, optimizing robotic grinding processes has never been more crucial.

With advancements in technology and the integration of smart systems, companies are now able to achieve remarkable gains in production rates—an increase of up to 30% is not uncommon for those who effectively implement best practices. In this article, we will explore the top five essential tips for optimizing robotic grinding efficiency, providing actionable insights that can transform your production capabilities and deliver a robust return on investment. By focusing on key strategies tailored to the unique challenges of robotic grinding, organizations can unlock their full potential and stay ahead in a competitive marketplace.

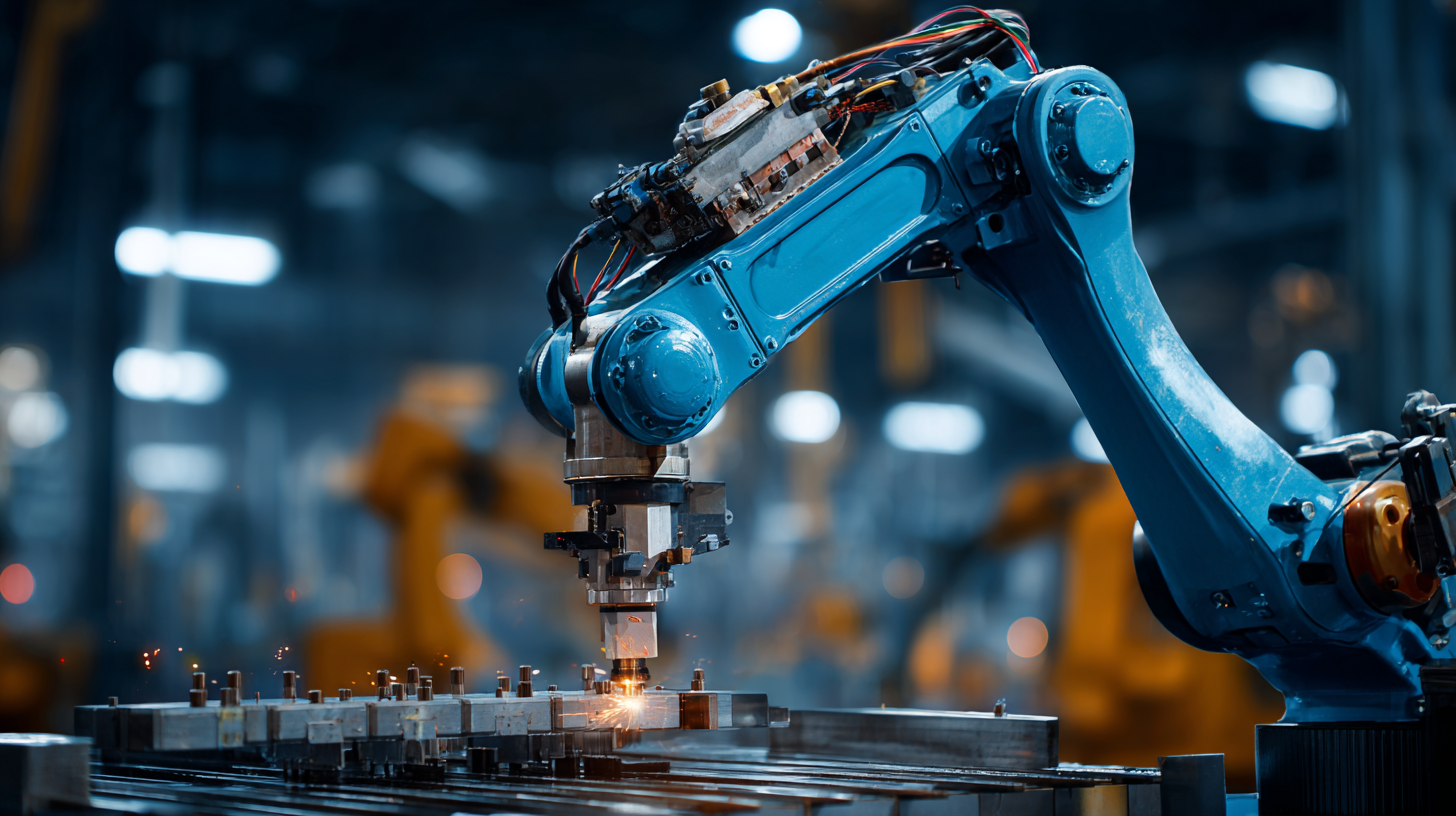

Understanding the Basics of Robotic Grinding and Its Importance in Manufacturing

Robotic grinding, a critical process in modern manufacturing, significantly enhances production quality and efficiency. According to a report by the International Federation of Robotics, the global stock of operational industrial robots reached approximately 2.7 million units in 2020, a figure projected to grow by 10% annually. This surge underscores the increasing reliance on robotic automation across various sectors, notably in grinding applications where precision and speed are paramount.

Understanding the basics of robotic grinding involves recognizing its key benefits, such as consistent quality, reduced cycle times, and improved safety. A comprehensive study conducted by the Manufacturing Technology Association revealed that companies employing robotic grinding solutions have achieved production efficiency improvements of up to 30%. This enhancement can be attributed to factors such as optimized tool paths, reduced human error, and the ability to perform complex geometries that manual methods find challenging. As manufacturers continue to adopt these technologies, the role of robotic grinding will only grow, making it an essential area of focus for competitiveness in the industry.

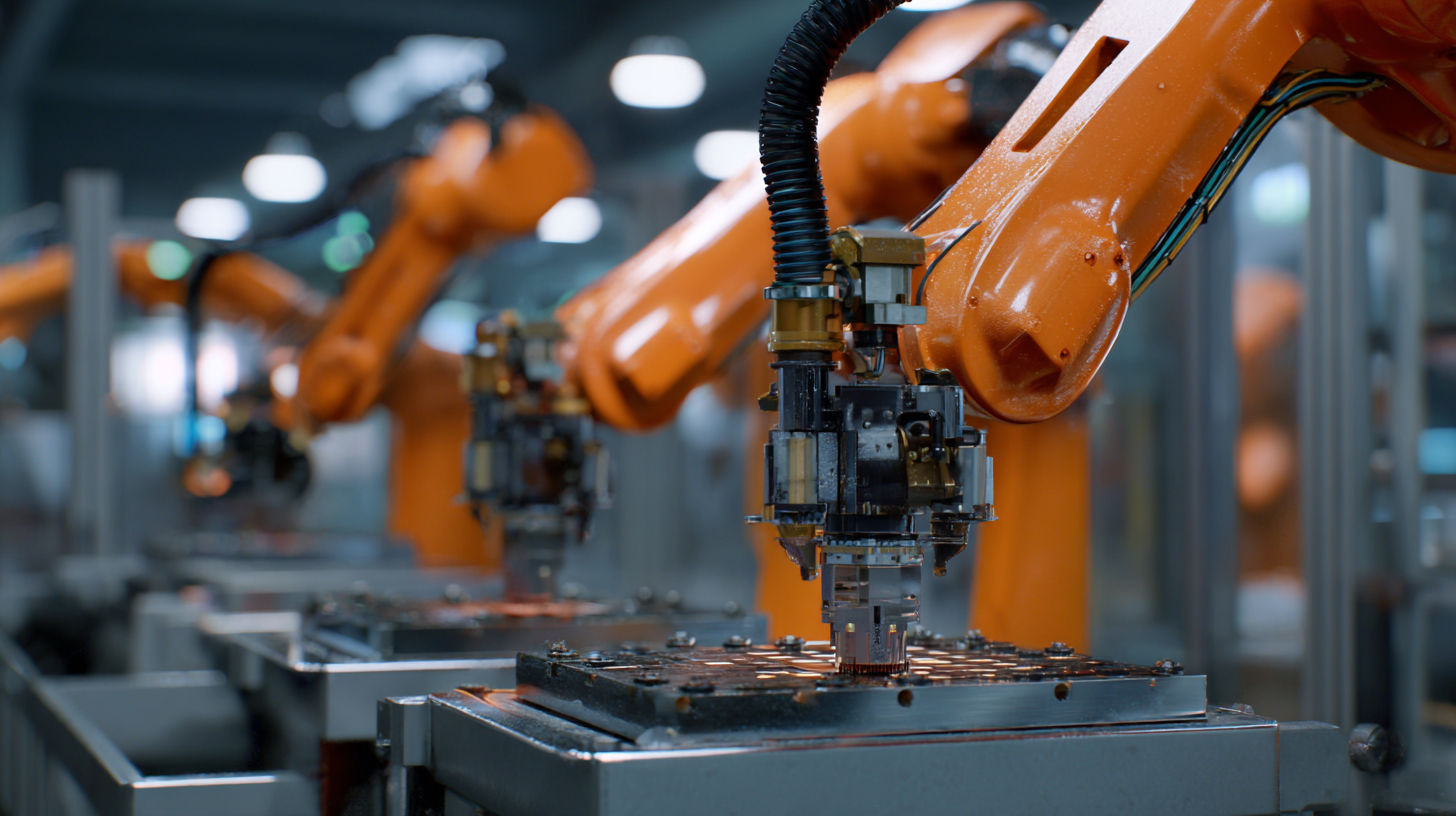

Key Factors Affecting Robotic Grinding Efficiency in Production Systems

Robotic grinding efficiency is crucial in modern production systems, and several key factors significantly influence its performance. According to a recent industry report by the International Federation of Robotics, 60% of manufacturers reported that optimizing robotic processes directly correlated with production speed and product quality. Variables such as tool selection, grinding parameters, and robot programming play critical roles in determining outcomes. For instance, the use of advanced grinding tools can lead to a reduction in cycle times by up to 25%, thereby enhancing overall system throughput.

Additionally, environmental settings such as temperature and humidity can impact grinding performance. A study by Manufacturing Insights indicated that fluctuations in these conditions could reduce robotic grinding effectiveness by 15%. Ensuring stable working environments and regular maintenance of robotic systems are essential practices that help mitigate these effects. As the industry continues to evolve, leveraging technology, such as real-time monitoring systems, can provide manufacturers with valuable data to fine-tune their robotic grinding operations for optimal efficiency.

Best Practices for Programming and Optimizing Grinding Paths

Optimizing grinding paths is critical for enhancing the efficiency of robotic grinding operations. One of the best practices is to employ advanced path planning algorithms. These algorithms can reduce cycle times by calculating the most efficient route for the grinding tool, minimizing unnecessary movements. By integrating machine learning, robots can learn from previous grinding tasks and adapt their paths for improved accuracy and speed, further reducing production time.

Another significant approach involves simulating grinding processes before executing them in the real world. Utilizing simulation software allows operators to visualize and refine the grinding path virtually, identifying potential collisions or inefficiencies. This pre-execution analysis can lead to adjustments that optimize the path, ensuring a smoother operation when it comes to the actual grinding task. Moreover, maintaining regular equipment calibration and updates can enhance the consistency of the results and prolong the lifespan of the robotic systems, ultimately leading to a significant boost in productivity.

Robotic Grinding Efficiency Optimization

Utilizing Advanced Sensors and Automation for Enhanced Grinding Performance

In the quest for optimizing robotic grinding efficiency, the integration of advanced sensors and automation stands out as a pivotal strategy. By utilizing cutting-edge sensors, manufacturers can achieve real-time monitoring of grinding parameters, which enables swift adjustments to maintain optimal performance. For instance, sensors that measure vibrational dynamics can detect anomalies in the grinding process, facilitating immediate intervention to prevent costly errors and material waste. This enhanced precision not only increases operational reliability but also contributes significantly to overall production rates.

Automation plays a crucial role in streamlining the grinding process as well. Sophisticated algorithms can analyze input from sensors, automatically adjusting grinding speeds and angles to meet the specific requirements of various materials. This level of adaptability not only maximizes material removal rates but also enhances surface finish quality. Incorporating robotics with these automated systems establishes a more coherent workflow, reduces operator fatigue, and minimizes human error, effectively driving production efficiency upwards. The combination of advanced sensors and automation is, thus, key to achieving an approximate 30% boost in overall grinding performance.

Regular Maintenance and Upgrades: Ensuring Long-term Efficiency in Robotic Grinding Systems

Regular maintenance and upgrades are critical for ensuring the long-term efficiency of robotic grinding systems. Consistent maintenance not only helps in identifying potential issues before they escalate into major failures but also maximizes the lifespan of the machinery. Scheduling routine checks can improve the performance of robotic arms, grinding tools, and sensors, ensuring that they operate at peak efficiency. Keeping machinery clean and lubricated reduces friction, minimizes wear, and maintains precision, which is fundamental in any grinding operation.

In addition to routine maintenance, timely upgrades play a significant role in enhancing efficiency. As technology evolves, new tools and software are developed that can substantially improve grinding processes. Upgrading to more advanced robotics can lead to faster cycle times and better surface finishes. Implementing updated software solutions can optimize the grinding parameters, allowing for greater flexibility in adapting to different materials and requirements. By investing in both maintenance and upgrades, companies can not only sustain efficiency but also achieve increased productivity and competitive advantage in their grinding operations.

Related Posts

-

The Future of Manufacturing Embracing Robotic Welding Systems and Their Impact on Industry

-

Revolutionizing Industries with Robotic Systems A Deep Dive into the Future of Automation

-

Revolutionizing Manufacturing: The Impact of Automated Welding Cells on Production Efficiency

-

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

-

2025 Top 5 Automated Welding Robots Revolutionizing Efficiency with 30% Productivity Increase

-

Exploring the Future of Work with Robotic Automation Solutions