2025 Top 5 Robotic Systems Transforming Industries with 50% Efficiency Boost

In the rapidly evolving landscape of modern industries, the integration of robotic systems has emerged as a pivotal force driving efficiency and productivity. As we look towards 2025, a new wave of innovative robotic technologies promises to transform various sectors, enhancing operational capabilities by an impressive 50%. Dr. Emily Chen, a leading expert in robotics and automation, emphasizes the significance of these advancements, stating, “The future of manufacturing lies in our ability to harness robotic systems that not only increase efficiency but also redefine the potential of what we can achieve in our workflows.”

The rise of advanced robotic systems is not just a trend; it's a necessary evolution for industries aiming to remain competitive in a global market. From automotive assembly lines to warehousing logistics, these systems are engineered to optimize processes, reduce human error, and ultimately drive down operational costs. With the ongoing innovations in artificial intelligence and machine learning, the role of robotics will continue to expand, enabling businesses to unlock new levels of efficiency and productivity.

As we delve into the top five robotic systems projected to revolutionize industries by 2025, it is crucial to understand how these technologies will shape the future of work. By examining their functionalities and the sectors they impact, we uncover the immense potential that robotic systems hold in paving the way for a more efficient, automated, and intelligent industrial landscape.

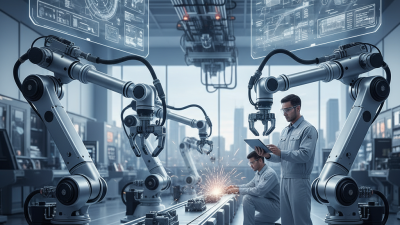

Revolutionizing Manufacturing: The Rise of Collaborative Robots and Their Efficiency Gains

The emergence of collaborative robots, or cobots, is set to revolutionize the manufacturing sector, significantly enhancing operational efficiency. According to a report by ABI Research, the global collaborative robot market is expected to reach $7.5 billion by 2025, fueled by a growing demand for automation and greater efficiency in production lines. Unlike traditional industrial robots, cobots are designed to work alongside human operators, allowing for a seamless integration into workflows and reducing the need for extensive safety measures. This synergy not only boosts productivity but also minimizes labor costs, with companies reporting efficiency gains of up to 50% when implementing cobot systems.

Furthermore, the International Federation of Robotics (IFR) states that businesses incorporating cobots are witnessing significant reductions in downtime and enhanced flexibility. By automating repetitive and ergonomic tasks, manufacturers can allocate human workers to more complex and value-added activities, thereby optimizing the overall production process.

As a testament to their effectiveness, a study by the Fraunhofer Institute found that 86% of companies utilizing collaborative robots reported improved operational efficiencies within the first six months of implementation. This transformative technology is paving the way for a new era of manufacturing, where human-robot collaboration is not just a possibility but a key driver of industry progress.

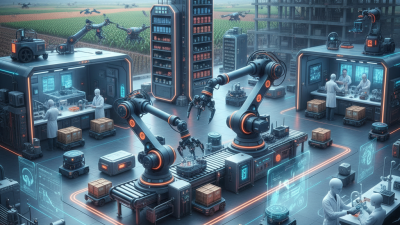

AI-Powered Automation in Logistics: Streamlining Supply Chains with Robotics

The integration of AI-powered automation in logistics is fundamentally reshaping supply chains, leading to significant efficiency boosts. Precision sorting is at the forefront of this transformation, enabling logistics operations to respond to the demands for speed and accuracy in today's fast-paced market. By employing advanced robotic systems, supply chains can enhance their capabilities to move goods seamlessly while minimizing human error and operational delays.

Recent investments in robotics reflect a growing commitment to harnessing AI for greater productivity. Companies are pouring substantial resources into developing automated systems that streamline warehouse operations and optimize logistics workflows. This shift not only enhances efficiency but also creates new job opportunities that require specialized skills in automation and machine learning. As these technologies evolve, they are expected to drive significant changes in how logistics professionals approach supply chain management, ultimately leading to more resilient and agile operations.

2025 Efficiency Boost in Robotic Systems Across Industries

In 2025, various robotic systems are projected to enhance efficiency in different industries significantly. The chart below illustrates the estimated efficiency improvement (%) across five key sectors utilizing AI-powered automation and robotics.

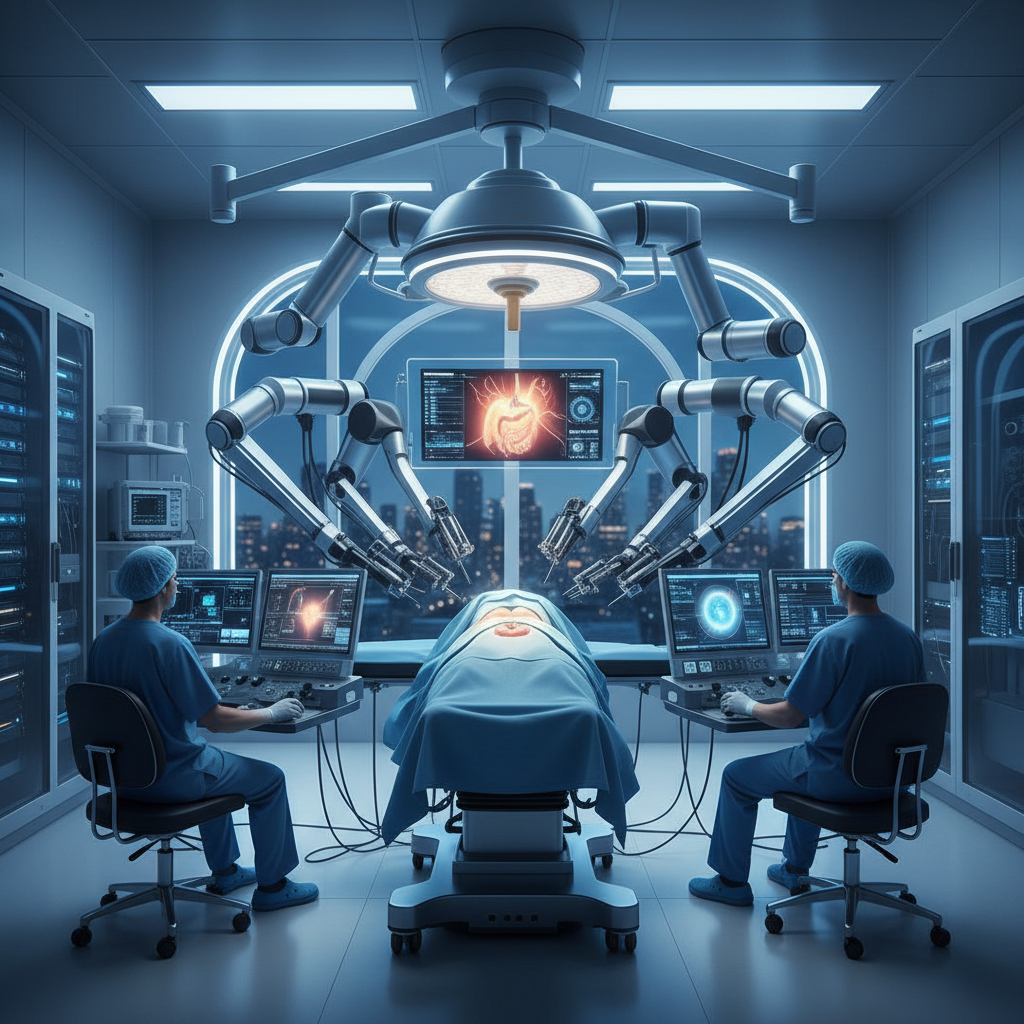

Healthcare Transformation: Robotic Surgery Systems Enhancing Precision and Speed

In the rapidly evolving field of healthcare, robotic surgery systems are setting new standards by enhancing precision and speed during operations. These advanced technologies allow surgeons to perform intricate procedures with minimal invasiveness, resulting in reduced recovery times for patients and fewer complications. By utilizing robotic arms equipped with high-definition cameras and sophisticated instruments, surgeons can operate with unparalleled accuracy, reducing the risk associated with traditional surgical methods.

Tips for integrating robotic surgery into healthcare facilities include investing in comprehensive training for surgical teams. Proper training ensures that surgeons and staff can fully leverage the capabilities of these systems, optimizing their use for different types of procedures. Furthermore, continuous assessment of surgical outcomes can help healthcare providers identify best practices and refine protocols to enhance patient care.

Additionally, collaboration between robotics engineers and medical practitioners is crucial. This partnership can lead to innovative solutions tailored to the specific needs of healthcare practitioners, enabling them to push the boundaries of surgery. As these robotic systems continue to transform the industry, the focus should remain on harnessing their full potential to improve patient outcomes and redefine the standards of care.

Agricultural Robotics: Increasing Yield and Reducing Labor Costs with Smart Systems

The agricultural robotics market is poised for remarkable growth, projected to surge from $8.13 billion in 2025 to $26.35 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 18.3%. This rapid expansion highlights the increasing adoption of smart systems that are revolutionizing the farming landscape. Advanced agricultural robots are designed to enhance yield while minimizing labor costs, enabling even those without farming experience to effectively manage crops through sophisticated AI-driven systems.

With innovations such as drone-assisted monitoring and automated irrigation, farmers can now manage their fields with unprecedented efficiency. For instance, AI technology enables farmers to "communicate" with crops, ensuring optimal conditions for growth without the need for manual labor. As a result, farms can achieve higher productivity and sustainability while addressing labor shortages in the agricultural sector.

Tip: To maximize the benefits of agricultural robotics, consider investing in a comprehensive smart farming system that integrates autonomous equipment with real-time data analytics. This can lead to better decision-making and improved crop management. Additionally, staying updated with industry trends and technological advances is crucial for maintaining a competitive edge in the rapidly evolving agricultural landscape.

Construction Industry Innovations: How Drones and Robotics Boost Project Efficiency by 50%

In the fast-evolving landscape of the construction industry, innovations such as drones and robotics are revolutionizing project management and execution. These advanced technologies are not only streamlining workflows but also significantly enhancing efficiency, achieving remarkable boosts of up to 50%. Drones, equipped with high-resolution cameras and sensors, provide real-time aerial surveillance, allowing project managers to monitor progress, conduct land surveys, and identify potential issues without the need for manual inspections. This reduces downtime and improves decision-making, ultimately leading to quicker project completion.

Robotic systems, on the other hand, are transforming manual labor by automating tasks such as bricklaying and concrete pouring. These machines work alongside human workers, handling repetitive and physically demanding jobs, which reduces the risk of injury and enhances productivity. By integrating robotics into construction processes, companies can minimize errors, ensure consistent quality, and adhere to schedules more effectively. The synergy between drones and robotics in the construction industry marks a pivotal shift towards a more efficient, safer, and technologically advanced operational framework.

2025 Top 5 Robotic Systems Transforming Industries with 50% Efficiency Boost

| Robot System | Industry Application | Efficiency Boost (%) | Key Benefits |

|---|---|---|---|

| Autonomous Drones | Construction Site Monitoring | 50% | Real-time surveillance and data collection |

| Robotic Arms | Material Handling | 50% | Increased precision and reduced labor costs |

| Automated Vehicles | Site Logistics | 50% | Streamlined transportation of materials |

| 3D Concrete Printers | Building Construction | 50% | Reduced waste and faster construction time |

| Inspection Robots | Structural Integrity Assessments | 50% | Early detection of issues, enhancing safety |

Related Posts

-

Exploring the Future: Top Robotic Systems to Watch in 2025

-

Unlocking Efficiency: How Robotic Automation Solutions are Transforming Everyday Business Operations

-

Exploring the Future of Work with Robotic Automation Solutions

-

Revolutionizing Industries with Robotic Systems A Deep Dive into the Future of Automation

-

2025 Top 10 Robotic Automation Solutions Transforming Industries Worldwide

-

10 Best Robotics and Automation Solutions Transforming Industries Today