Top 10 Robotic Welding Classes to Enhance Your Skills in 2023

In the rapidly evolving landscape of manufacturing and engineering, the integration of robotics has revolutionized traditional processes, particularly in welding. Robotic welding classes have emerged as a crucial opportunity for professionals seeking to enhance their skills and stay relevant in an increasingly automated industry. As automation continues to enhance efficiency and precision, understanding the technological advancements in robotic welding becomes essential for anyone aspiring to excel in this field.

In 2023, a diverse array of robotic welding classes is available, catering to varying levels of expertise and specialization. Whether you are a novice looking to develop foundational skills or an experienced welder aiming to refine advanced techniques, these educational programs offer invaluable insights into the operation and programming of robotic systems. By engaging in hands-on training and theoretical knowledge, participants will not only improve their technical abilities but also gain a competitive edge in the job market.

By exploring the top ten robotic welding classes available this year, we aim to provide a comprehensive guide for aspiring welders and seasoned professionals alike. These classes will equip you with the necessary tools and knowledge to thrive in the demanding yet rewarding field of robotic welding, ultimately paving the way for a successful career in this high-tech domain.

Understanding the Importance of Robotic Welding Skills in 2023

In 2023, the landscape of manufacturing and production is increasingly defined by automation, making robotic welding skills more crucial than ever. As industries strive for efficiency, precision, and quality, robotic welding stands out as a transformative technology that enhances productivity while reducing human error. Understanding robotic welding not only provides a competitive edge in the job market but also equips professionals with the capabilities to operate advanced machinery, program robots, and troubleshoot systems effectively.

The demand for skilled technicians in robotic welding is on the rise, with industries such as automotive, aerospace, and construction relying on these automated processes to meet their production goals. Mastery of robotic welding techniques enables individuals to contribute to the development of high-quality products and innovative solutions within their organizations. As companies continue to invest in automation to enhance their workflows, those equipped with strong robotic welding skills will find themselves at the forefront of this technical evolution, positioning themselves as valuable assets in the workforce.

Robotic Welding Skills Enhancement in 2023

Key Features of Effective Robotic Welding Classes

When looking for effective robotic welding classes, several key features should be highlighted to ensure a comprehensive learning experience. First and foremost, hands-on training is essential. Practical experience with state-of-the-art robotic equipment allows students to familiarize themselves with the technology, understand its capabilities, and troubleshoot common issues that may arise during welding processes. Classes that incorporate real-time simulations and live demonstrations offer an immersive environment where learners can develop their skills effectively.

Another important aspect to consider is the curriculum's depth and relevance. A well-structured program should cover fundamental concepts of robotic welding, including programming, safety protocols, and automation techniques. Additionally, the inclusion of advanced topics, such as integration with CAD software and process optimization, can significantly enhance the educational experience. Instructors with industry experience can provide valuable insights into current industry standards and best practices, equipping students with the knowledge they need to excel in their careers.

Lastly, the availability of ongoing support and resources is a vital feature of any effective class. This includes access to online forums, additional training materials, and opportunities for networking with industry professionals. Such resources help reinforce learning beyond the classroom, allowing students to stay updated with the latest advancements in robotic welding technology and methodology.

Top 10 Robotic Welding Programs to Consider

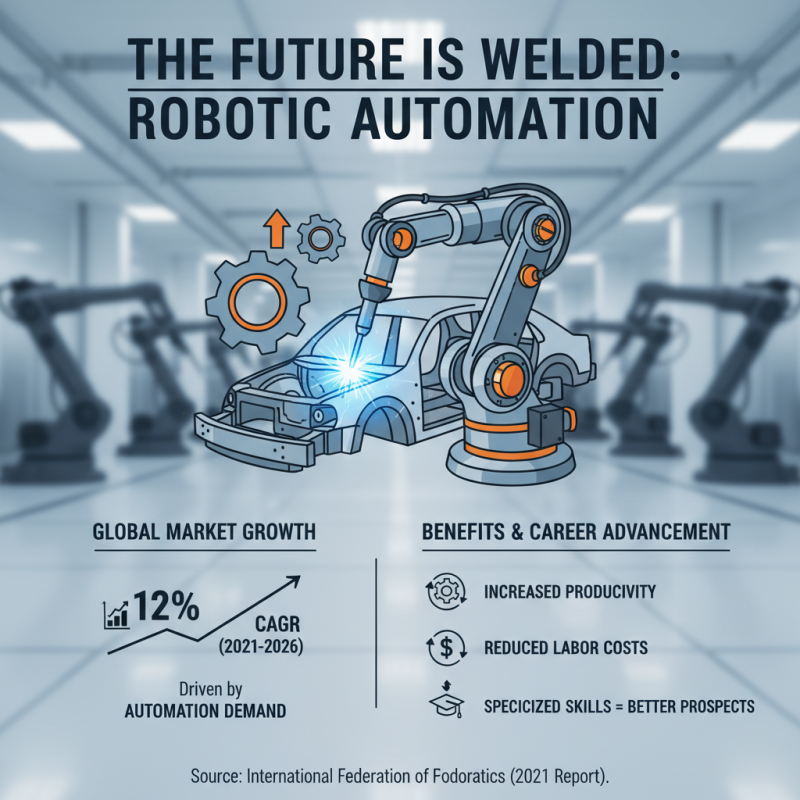

In recent years, robotic welding has become an essential skill in the manufacturing and automotive industries, with a notable rise in its application across various sectors. According to a report by the International Federation of Robotics, the global market for robotic welding systems is projected to grow significantly, with an expected CAGR of 12% from 2021 to 2026. This growth is fueled by the increasing demand for automation in welding processes, which enhances productivity and reduces labor costs. As a result, individuals looking to enhance their career prospects would greatly benefit from enrolling in specialized robotic welding programs.

When considering educational options, prospective students should look for programs that provide hands-on training in robotic systems, programming, and operational safety. Comprehensive courses often include a blend of theoretical knowledge and practical applications, covering the latest advancements in welding technology. Data from the Bureau of Labor Statistics highlights that skilled welders who are proficient in robotic welding can expect to see higher wages and improved job security, further emphasizing the importance of pursuing specialized training. With the growing need for skilled professionals, the right robotic welding program can offer a strong foundation for a successful career in this evolving field.

Tips for Choosing the Right Robotic Welding Class for You

When considering a robotic welding class, the first step is to assess your current skill level and objectives. This will help you to identify whether you need a beginner course focusing on the fundamentals of robotic welding or an advanced class aimed at refining your technical abilities. Understanding your career goals is crucial—if you aim for a specific industry or position, seek out programs that offer specialized training relevant to those needs.

Next, consider the format and structure of the course. Some programs are offered in-person, while others may provide online or hybrid options. Review the curriculum to ensure it covers essential topics such as programming, safety protocols, and troubleshooting. Additionally, look for classes that offer hands-on experience, as practical application is vital in mastering robotic welding techniques. Be sure to check the qualifications of the instructors, as experienced educators can greatly enhance the learning experience by providing valuable insights and real-world scenarios.

Future Trends in Robotic Welding Training and Technology

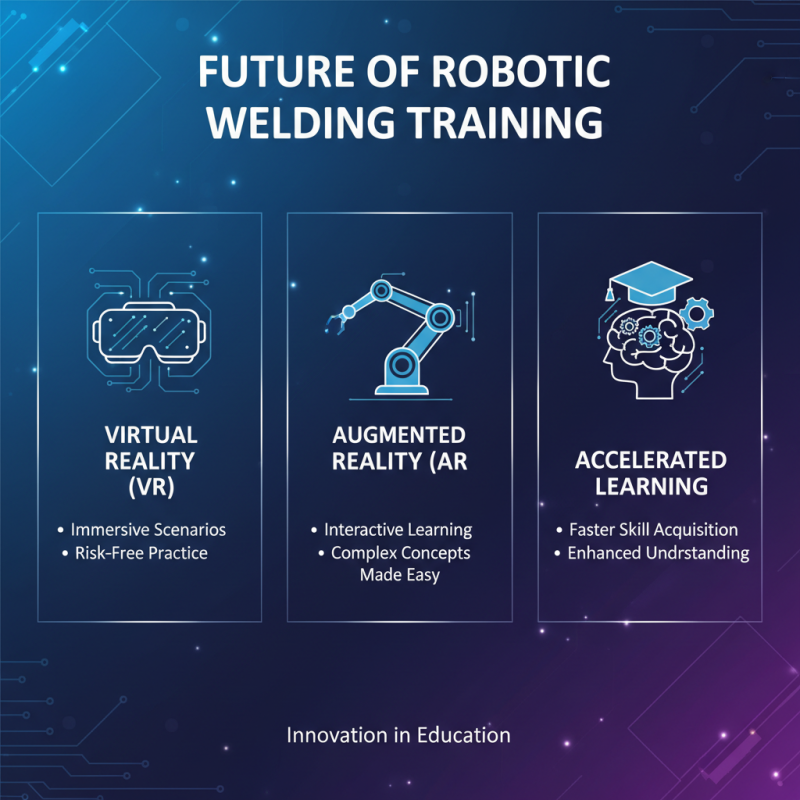

As we look towards the future of robotic welding training, significant advancements in technology are shaping the landscape of education in this field. One trend is the increasing integration of virtual reality (VR) and augmented reality (AR) tools into training programs. These technologies allow students to immerse themselves in realistic welding scenarios, enhancing their hands-on skills without the inherent risks associated with actual welding. By providing an interactive learning environment, VR and AR can accelerate the learning curve, making complex concepts more accessible and understandable for learners at all levels.

Another notable trend is the growing emphasis on automation and smart technology in welding education. As industries embrace Industry 4.0, training programs are incorporating advanced algorithms and data analytics to teach students how to optimize robotic welding processes. This includes understanding how to program and troubleshoot welding robots effectively, as well as leveraging data to improve efficiency and product quality. The incorporation of such technologies not only enhances the skill set of aspiring welders but also prepares them for a job market that increasingly values tech-savvy employees who can adapt to rapid industrial changes.

Related Posts

-

2025 Top 5 Robotic Welding Classes for Advanced Skills and Career Growth

-

Revolutionizing Industries with Robotic Systems A Deep Dive into the Future of Automation

-

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

-

How to Harness Robot Technology for Everyday Life and Enhance Productivity

-

Exploring the Future: Top Robotic Systems to Watch in 2025

-

Top 10 Benefits of Using Robotic Welding Machines in Modern Manufacturing